A conduit standoff bracket is a component used to support and secure conduits, cables or communication lines. The bracket helps to keep them at a safe distance from other conductors, structural components or the ground. It is also known as a cable standoff bracket or conduit hanger bracket. It helps to maintain the safety and functionality of the systems. This is by preventing contact and interference between conductors. It also helps to ensure proper alignment and tension of cables and conduits. A conduit standoff bracket is from materials like steel, aluminum or fiberglass. These are capable to withstand outdoor environmental conditions in South America. Common examples include clevis hanger bracket, adjustable bracket, heavy-duty bracket and twist angle standoff bracket. They find use in applications such as power distribution, telecommunication, urban infrastructure, agriculture and mining.

Key features of conduit standoff bracket

There various features help to support and secure conduits, cables and communication lines. The available features depend on the specific application and environmental conditions. The following are the key features of the conduit standoff bracket.

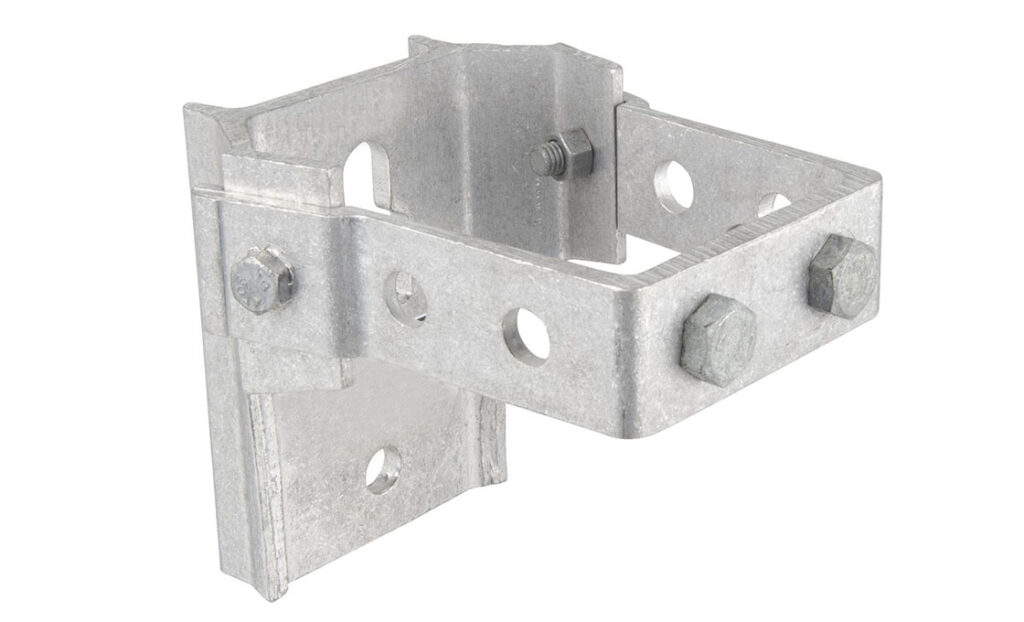

- Corrosion resistance – many of the brackets have coatings, galvanization and materials. They help to resist rust and deterioration for longer serviceable life.

- Adjustability – this allows for fine-tuning of the distance between the supported conduit and the structure. This helps to maintain proper tension and alignment of the application.

- Load capacity – the brackets are able to support specific load capacities. This ensures they can support the weight of the conduits, cables or lines.

- Electrical insulation – some brackets are able to provide electrical insulation. They help to prevent electrical arcing with the conductors.

- Durability – they brackets are able to withstand the environmental conditions and mechanical stresses. This is to ensure long-term performance and reliability.

- Material – they are from durable materials such as steel, aluminum or fiberglass. They offer strength and resistance to environmental conditions.

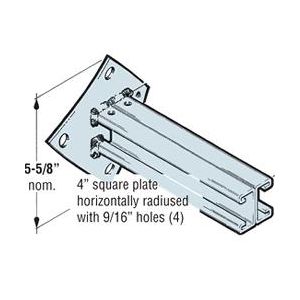

- Design – they are available in different designs to suit the various applications. They have features like straight arms, adjustable angles, clevis hangers and U-bolts.

- Fastening – they have mounting holes or brackets for secure attachment to support structures.

- Attachment points – may brackets have attachment points to secure conduits, cables or lines in place.

Selection and installation of conduit standoff bracket

Proper selection ensures the safe and effective support of conduits, or cables. It includes considering various factors that influence the selection and use of the brackets. These factors include conduit size, load capacity, environmental conditions, material, load distribution and ease of installation. The installation should also ensure the safe and reliable support of conduits. Additionally, it is advisable to consult with experts in the industry for guidance on the installation whenever in doubt. The following is a basic guide for the installation of the conduit standoff bracket.

- Preparation – collect all the necessary tools required for the installation. This includes conduit standoff bracket, fasteners, wrenches and sockets, measuring tape, marking tools and safety gear.

- Inspection – inspect the installation area and determine the optimal location for the bracket.

- Bracket preparation – examine the conduit standoff bracket to ensure it is in good condition.

- Mark the mounting holes – use a measuring tape to mark the locations for the mounting holes.

- Drill holes – use the appropriate tools to create hole matching the size and spacing of the brackets mounting holes.

- Bracket attachment – attach the conduit standoff bracket to the structure using suitable fasteners. This includes bolts, nuts and washers.

- Conduit mounting – mount the conduit, cable or communication lines to the bracket. Ensure they are properly positioned and use the recommended attachment points.

- Adjustment – fine-tune the distance between the conduit and the structure. This helps to meet your project requirements.

- Compliance – ensure the installation complies with the safety standards and regulations.

- Final inspection – conduct a thorough visual inspection to confirm security, alignment and compliance with safety standards.

Maintenance and inspection of conduit standoff bracket

Maintenance and inspection ensure the continued safe and reliable support of conduits. It also helps identify and address issues that could lead electrical faults and safety hazards. Additionally, it is advisable to perform professional maintenance and inspection once in a while. The frequency helps depends on the environmental conditions in the region. The following is a basic guide for inspection and maintenance of the bracket.

- Establish a routine inspection schedule which varies depending on factors like environmental conditions.

- Perform visual inspections of the bracket. Check for signs of damage, wear, corrosion and irregularities.

- Consider the environmental factors such as exposure to saltwater in coastal areas.

- Ensure the insulating properties remain intact to provide electrical insulation if applicable.

- Clean the brackets to remove dirt, debris and vegetation that accumulates on the bracket.

- Inspect the brackets for signs of corrosion and apply anti corrosion coatings and treatments.

- Inspect the brackets for signs of corrosion and apply anti corrosion coatings and treatments.

- Apply lubricants to moving parts to ensure smooth adjustments and prevent wear.

- Replace the damaged brackets that show signs of wear to maintain the structural integrity.

- Check the alignment and tension of the supported conduit or cables to ensure safety and electrical reliability.

- Use remote monitoring systems to continuously assess the condition of the standoff brackets.

- Maintain detailed records of the inspection dates, findings and maintenance actions taken.

Comparative analysis of conduit standoff brackets in South America

A comparative analysis involves assessing and evaluating various aspects of the essential components. It includes assessing factors like material, design, applications and regional considerations. The choice of the bracket type depends on the specific needs of the application and other factors. Also, it is advisable to consult with industry experts for guidance on the selection process. The following are the common factors to include in a comparative analysis in South America.

- Materials – there are various materials used to manufacture the conduit standoff bracket. These include steel, aluminum and fiberglass. Assess the benefits and limitation of each of the materials depending in the environmental conditions. They should offer strength, durability, corrosion resistance and lightweight properties.

- Design – there are various designs of the conduit bracket to select from in the market. Some of the designs include straight arm brackets, adjustable brackets and clevis hangers. They should offer alignment and secure attachment.

- Application – conduit standoff brackets find use in applications such as electrical power distribution, telecommunication, renewable energy, mining and agriculture. Assess how well the bracket suits the application and the environmental conditions.

- Regional considerations – assess the regional aspects in the installation area. South America has various aspects to consider that include coastal regions, extreme environments, regulations, rural electrification and cost considerations.

Certifications and standards in South America

Certifications and standards help to ensure the safety, quality and performance of brackets. Each south American country has their own set of standards and certifications. Some countries also adopt the international standards for electrical components. Additionally, ensure the selected conduit standoff bracket complies with the relevant industry standards. The following are the common standards and certifications in South America.

- ISO certifications – this sets international standards relevant to conduit standoff brackets. They help to ensure quality, safety and performance of the conduit standoff bracket.

- IEC standards – this provides standards related to electrical and electronic technologies in South America.

- Regional electrical codes – there are regional electrical codes and regulations specific to each country.

- CE marking – this indicates the product complies with European union safety and environmental standards.

- Local regulations – some countries may have specific electrical and construction regulations for conduit standoff bracket.

Regional market for conduit standoff bracket in South America

There are various factors and trends that influence the regional market for conduit standoff brackets in South America. These factors include economic development, infrastructure projects and industrial growth. These factors influence the demand and availability of conduit standoff in the market. Additionally, manufacturers should observe the dynamics to understand the market well. The following are the factors that influence the regional market for the brackets.

- Telecommunication networks – the development of 4G and 5G networks require the use of the brackets to support internet access.

- Renewable energy – conduit standoff brackets work in renewable energy sources. These technologies include wind farms and solar panels.

- Rural electrification – conduit standoff brackets help to bring electricity to remote and underserved areas.

- Data centers – they also help to support the extensive cabling systems required for data and communication networks.

- Government initiatives – the initiatives aimed at improving infrastructure and enhancing rural electrification programs contribute to the market for brackets.