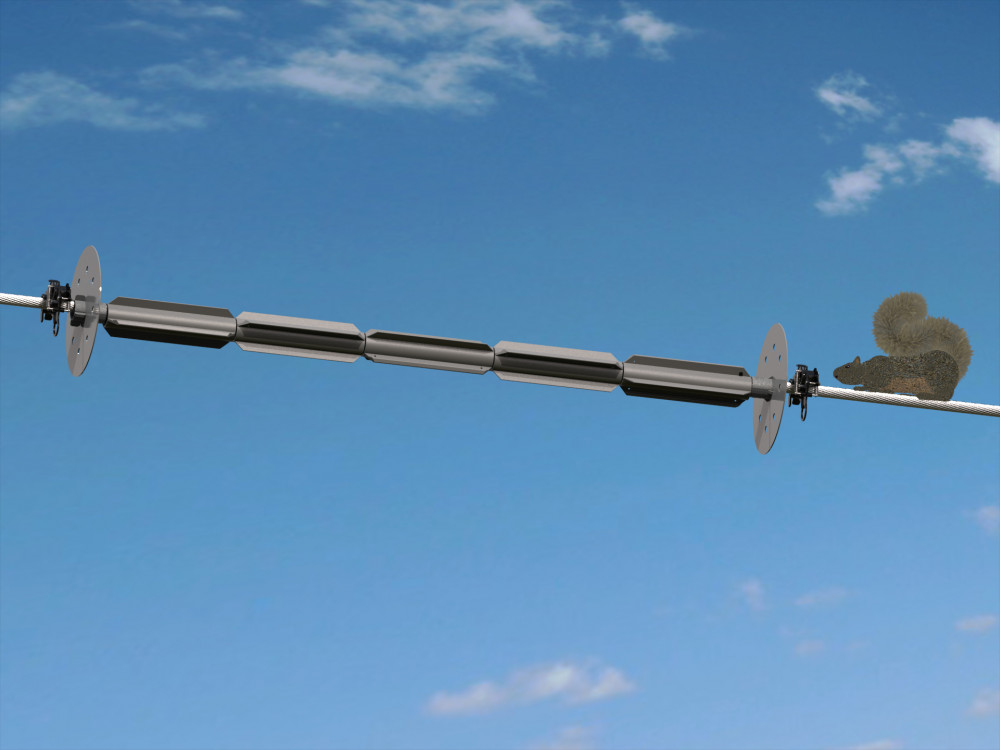

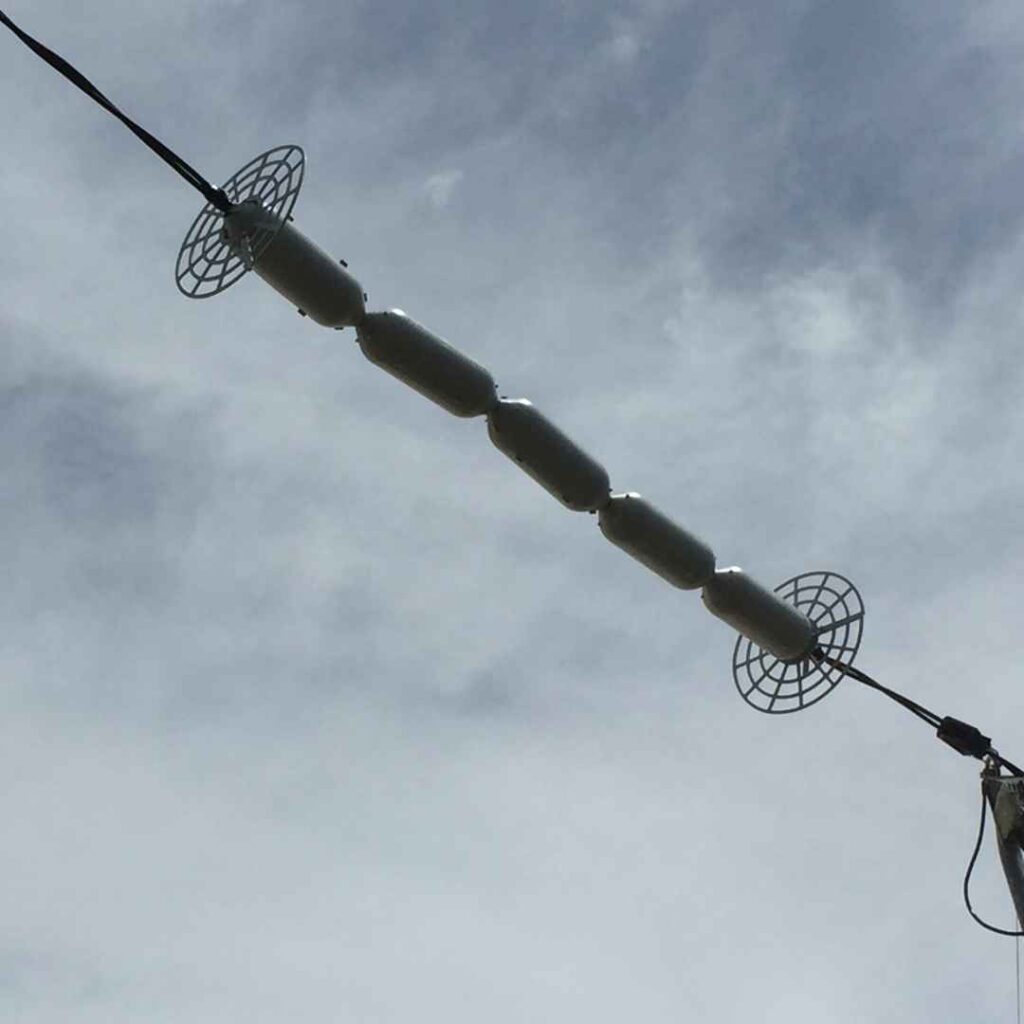

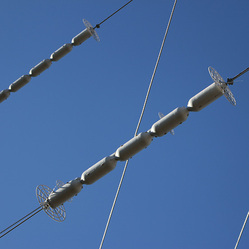

A line guard is a component used in overhead transmission lines and electrical systems. It serves to protect the integrity and functionality of the conductors. The devices protect the integrity of electrical transmission. They also ensure the safety of the infrastructure. The line guard protects conductors from mechanical stress and environmental damage. It consists of helical wire components that wrap around the conductor. This protects against a variety of risks. They also shield conductors from physical damage caused by environmental conditions. These could be due to shaking, galloping, or contact with branches. Line guards are from materials that are durable, reliable, and corrosion resistant. These materials include aluminum, steel, composites, and copper. Common types include spiral line guards and rod type line guards.

Accessories associated with a line guard

Line guards work with a variety of accessories to increase their effectiveness, assure proper installation, and maintain integrity. The accessories aid in protecting the conductors, reducing damage, and optimizing the function of the line protectors. This also helps to increase visibility and defend against environmental threats. The following are common accessories for line guards.

- Vibration dampers – these help to reduce the impact of aeolian vibrations caused by wind. These can lead to conductor fatigue and eventual failure.

- Armor rods – the rods protect the conductors from mechanical damage and stress at points where they clamp.

- Spacer dampers – these serve to keep conductors in multi-conductor bundles separated and aligned. They work in bundled conductors to maintain spacing and reduce vibrational damage.

- Preformed ties – the ties secure the conductor to the insulator without causing damage. It consists of helical-shaped wires that wrap around the conductor and insulator.

- Line guard cushions – they are from layers placed between the line guard and the conductor. This helps to prevent abrasion and ensure a snug fit.

- Corona rings – corona rings distribute electrical stress along the conductor and reduce corona discharge. They are essential for high voltage lines where electrical discharge needs control.

- Armor clamps – these secure armor rods or line guards in place to ensure they do not shift along the conductors. They help to attach line guards in areas with significant mechanical stress.

- Insulator guards – these protect insulators from damage and contamination. This may be from debris, birds, and weather elements. They install near line guards to ensure the insulators and conductors remain clean and functional.

- Line guard connectors – these help to join sections of the line guards allowing for continuous protection along longer spans. They have designs to fit and ensure seamless protective layer.

Choosing the Best Line Guard for Your Application

Line guards are available in a variety of styles and types to suit your specific needs. Choosing the best line guards requires careful consideration of many factors. This is to ensure they provide enough protection, durability, and efficiency. The selection method depends on the climatic conditions, the type of conductor, and any risks. The following are the variables to consider while choosing the best line guard for your needs.

- Environmental conditions – check the weather patterns, pollution, levels and wildlife interference. These conditions may include wind speeds, ice accumulation and temperature fluctuations. Select line guards that are able to withstand resistance to wind-induced vibrations and fatigue. They should also have corrosion properties to resist chemical degradation.

- Conductor type and size – check the conductor material, diameter and configuration. The selected line guard should reduce galvanic corrosion, match specific diameter and type of conductor for optimal protection.

- Mechanical load and stress factors – select line guards that distribute mechanical stress and withstand high tension. They should also have designs to mitigate vibrational damage.

- Ease of installation and maintenance – consider the ease of applying and securing the line guards. They should be easy to install and remove without specialized tools.

- Compatibility with existing infrastructure – ensure the line guards are compatible with current conductors, insulators and other hardware. Consider the future expansions to the transmission line that might affect line guard needs.

- Costs – balance the upfront costs of line guards with the potential ling term savings in maintenance and damage prevention. Ensure the line guards come with a guarantee of performance and reliability.

Installation Procedure for Line Guards

To ensure security and optimal functioning, the installation process necessitates meticulous preparation and capabilities. It is also important to get professional help while installing line guards. The following is a step-by-step guide for installing line guards.

- Preparation and safety considerations – assess the installation site for accessibility, environmental conditions and potential hazards. Gather all the necessary tools and materials required for the installation process. Use personal protective equipment including hats, gloves, safety glasses and harnesses.

- Installing helical line guards – measure the length of the conductor use with the line guard and mark the starting point on the conductor. Wrap the helical line guard at the marked starting point and ensure it is secure and tight.

- Installing armor rods – prepare the rods by laying them down in the order they will install in and ensure they are clean and free of defects. Align the rods to ensure even spacing around the conductor when wrapped. Wrap the first rod around the conductor and ensure it is tight and properly aligned.

- Installing rod type line guards – position the line guard at the start point ensuring it aligns with the conductor. Use an armor clamp to secure the beginning of the line guard to the conductor.

- Inspection – check the entire length of the installed line guard for gaps or loose wraps. Ensure the line guard installs well and covers the conductor without any distortions.

- Tightening – tighten all the clamps and fasteners to ensure the line guard is secure and does not move. Verify the ends of the line guards wrap and clamp securely to prevent unravelling.

- Documentation – keep records of the installation details including the type of line guards used, location and other observations. Report the completion of the installation to relevant authorities and update maintenance records.

Inspection and maintenance procedures for line guards

Regular inspections and maintenance of line guards serve to ensure the systems’ long-term effectiveness and reliability. It also aids in the early detection of possible difficulties, extending the life of the line guards. Also, frequent maintenance avoids costly outages, extends the lifespan of their infrastructure, and ensures the safe and uninterrupted transmission of electricity. The following is a basic guide on maintaining and inspecting line guards on overhead transmission lines.

- Check for any visible damage such as cracks, breaks or deformations. Ensure the line guards align correctly and have not shifted. Look for signs of wear, abrasion on the line guards and conductors. Check for rust of other forms corrosion.

- Clear any debris or dirt that may affect the line guards’ performance using suitable cleaning agents to remove pollutants.

- Tighten any loose bolts or clamps to ensure secure attachment. Adjust the line guards that may have shifted to restore proper alignment. Apply lubricant to any moving parts or joints to prevent rust and ensure smooth operation.

- Use patch materials to repair small cracks or breaks in the line guards. Apply protective coatings to areas showing early signs of corrosion. Replace the damaged sections of the lien guard if the rest is in good condition.

- Apply anti-corrosion coating or treatments to extend the life of the line guards. Use cathodic protection techniques for severe corrosion-prone areas. Add extra layers or types of guards to strengthen the existing protection.

- Install spikes or other deterrents to prevent birds from perching on the line guards. Use protective covers to keep small animals from damaging the line guards.

- Document each inspection with details on the findings, condition of the line guards and any correction actions taken.

Frequently asked questions

Line guards provide a physical barrier that shields conductors from environmental elements, mechanical wear and impacts from external objects.

Accessories used with line guards include armor rods, spacer dampers, vibration dampers, conductor sleeves and bird diverters.

Environmental conditions like wind, heavy ice, extreme temperatures and pollution levels impact the effectiveness of the line guards.