A b strand ground clamp is a component used in overhead and electrical installations. It connects grounding conductors to the metallic support structures or cables. A b strand ground clamp ensures the messenger wire is properly grounded. This is to protect the system from lightning and other electrical surges. It also maintains the safety and integrity of the electrical system. This is by providing a consistent and low-resistance path to ground. A b strand ground clamp ensures a stable electrical connection for the functioning of the electrical grid. The grounding clamp has a U-bolt mechanism for easy installation and a secure connection. It is from materials like bronze, copper or other corrosion resistant metals to ensure durability. They also provide a reliable and stable connection to ensure the grounding system is effective in preventing electrical hazards.

Properties of a b strand ground clamp

The b strand ground clamp has several properties that ensure their effectiveness and reliability. These properties help to ensure the right selection of the b strand ground clamp for specific applications. The following are the common properties of the b strand ground clamp.

- Conductivity – South American b strand ground clamps high strength and durable materials. These are materials such as copper, bronze or galvanized steel. These materials have high electrical conductivity to ensure efficient grounding.

- Corrosion resistance – these clamps have coatings or materials that are resistant to corrosion. This helps to ensure long term durability in various environmental conditions.

- Size and compatibility – the clamps are available in different sizes. This is to accommodate various grounding conductors and support strands. They also include adjustable components to fit a range of cable and strand diameters.

- Design – they include fittings that ensure their secure attachments. This is to provide a secure and stable connection to the grounding conductor. These includes U-bolts, set screws, or clamping plates.

- Low resistance – the clamps should ensure a low resistance path to ground. This is essential for effective grounding. It also helps to reduce electrical hazards.

- Reliability – they should be able to maintain reliable electrical contact over time. This is especially in harsh environmental conditions.

- Weather resistance – the clamps should be able to withstand exposure to various weather conditions. These include UV radiation, rain, snow and temperature extremes.

- Longevity – they are able to ensure along service life with minimal maintenance needs. South American b strand ground clamps ensure long-term reliability of the grounding system.

- Tensile strength – they b strand ground clamps are able to handle the mechanical load and tension of the support strand.

- Vibration resistance – they have designs to remain secure and maintain electrical contact. They remain secure even in areas subject to vibration.

What are the components of a b strand ground clamp?

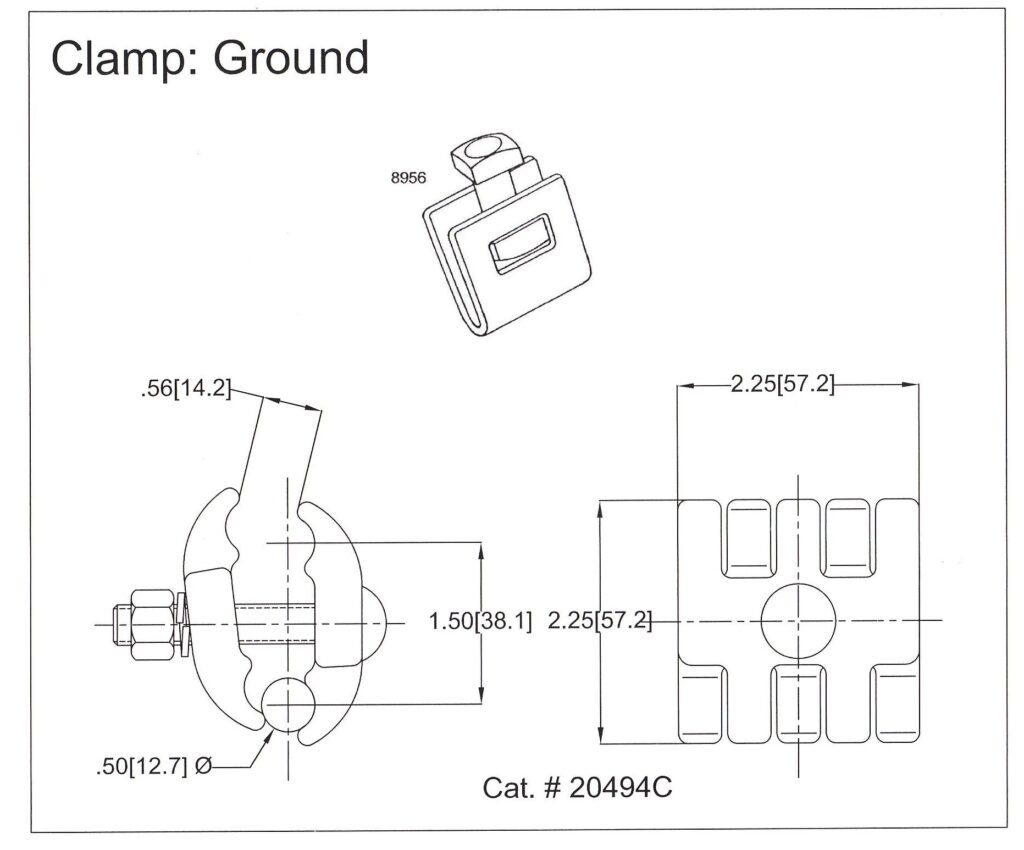

A b strand ground clamp consists of several key components designed to ensure secure and reliable grounding in overhead systems. Each of these components serve several functions in the overhead system. It also helps ensure proper installation and maintenance of b strand ground clamps. The following are the common components of a b strand ground clamp.

- Clamp body – this is the main structure that holds all other components together. It provides the primary conductive path between the grounding conductor and the support strand.

- Pressure plate – this distributes the pressure evenly even when the bolts tightened. It also ensures a secure and stable connection without damaging the conductors.

- Grounding conductor slot – this is a hole in the clamp body where the grounding conductor inserts. It provides a dedicated space for the grounding conductor to ensure proper alignment.

- Nut – this screws onto the bolts to tighten the clamp assembly and secure all components in place.

- Washer – this sits under the bolts, or nuts to distribute the load and prevent loosening due to vibration.

- U-bolt – this is a bolt that wraps around the support strand and the grounding conductor. It ensures a secure mechanical connection and maintains firm contact with the conductors. This is to provide a stable electrical connection.

Coatings and treatments for b-clamps

Use of coatings and treatments of the b strand ground clamp enhances the durability, conductivity and resistance to environmental factors. Also, the right selection of these coatings and treatments enhances the performance and longevity of the South American b strand ground clamps. Coatings and treatments provide corrosion resistance, improved conductivity, mechanical protection and aesthetic improvement. The following are the common types of coatings and treatments for b strand ground clamps.

- Galvanization – this is a process of applying a zinc coating to steel or iron to prevent rust and corrosion. The layer provides a barrier against moisture and oxygen to ensure durability.

- Tin plating – this is a layer of tin applied to the surface of the metal to enhance conductivity and provide corrosion resistance.

- Copper plating – this is a layer of copper deposited onto the metal surface to improve electrical conductivity. It also provides a degree of corrosion resistance.

- Bronze – this is a layer of bronze applied to the clamp to provide corrosion resistance and good electrical conductivity.

- Anodizing – this is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. It enhances corrosion resistance and wear resistance.

- Powder coating – this is a dry powder applied electrostatically and then cured under heat. Its purpose is to provide a protective layer that is tough, corrosion-resistant and can be color-coded for identification.

- Epoxy coating – this is a thermosetting polymer applied as a protective layer. It provides a strong adhesion, chemical resistance and durability.

Testing b strand ground clamps

There are several methods to testing a b strand ground clamp in overhead transmission lines. Testing provides a secure and reliable grounding connection. It also ensures that the b strand ground clamp installs and functions as expected. The following are the steps and methods for testing b strand ground clamps.

- Visual inspection – ensure the grounding conductor and support strand are free of dirt, corrosion and oxidation. Ensure the grounding conductor inserts into the designated slot and that the U-bolt or bolt assembly is tightly secured.

- Mechanical testing – use a torque wrench to check that the bolts and nuts are tight to the recommended specifications. Recheck the tightness to account for any loosening due to vibration or thermal expansion. Apply a controlled pull force to the grounding conductor and support strand. This is to ensure the clamp maintains a secure grip without slipping.

- Electrical testing – use a multimeter to check for electrical continuity between the grounding conductor and the support strand. A good connection shows low resistance which shows a proper electrical path. Perform a ground test using a ground resistance tester to measure the effectiveness of the grounding system.

- Environmental testing – expose the clamp to environmental conditions that simulate its operating environment. Check for any signs of corrosion or degradation over time. Subject the clamp to temperature variations to ensure it maintains its integrity and performance.

- Documentation – keep detailed records of all tests conducted on the overhead transmisison line. This is including the date, test parameters and results. Establish a regular inspection and testing schedule to ensure ongoing reliability of the grounding system.

Community forums and engagement for b strand ground clamps

Engaging in community forums is valuable for sharing information, troubleshooting and learning about the best practices. It also helps to solve problems and contribute to the collective expertise surrounding the b strand ground clamps. The following are some forums and ways to engage with the community.

- Electrical engineering stack exchange – this is a Q&A site for electrical engineering professionals and enthusiasts. They allow questions and sharing experiences related to the b strand ground clamps.

- IEEE communities – this is the institute of electrical and electronics engineers. They offer forums and groups of professionals in the electrical engineering field.

- Reddit – there are subreddits dedicated to electrical engineering topics including b strand ground clamps. Interactions include posting questions, sharing insights and discussions on various topics related to electrical systems.

- Eng-Tips Forums – this is platform for engineers to discuss technical issues and share solutions. They allow engaging in discussions, asking for advice and providing solutions to others.

- LinkedIn groups – there are professional groups on LinkedIn focused on electrical engineering and other fields.

- IEEE conferences – this organizes various conferences focused on electrical and electronics engineering. You can attend sessions, take part in workshops and network with industry experts.

- National Electrical Contractors Association Events (NECA) – this hosts events and expos for electrical contractors. You can engage with exhibitors, attend educational sessions and connect with other professionals.

- Manufacturer forums – some manufacturers of b strand ground clamps provide forums and support communities for their products.

- Facebook groups – these are groups dedicated to electrical engineering and related topics. Join groups, take part in discussions and share experiences in such groups.

Frequently asked questions

B strand ground clamps are from high conductivity metals such as bronze, copper or galvanized steel. This provides durability and effective electrical conductivity.

Corrosion resistance helps to prevent degradation of the clamp and ensure long-term reliability and safety in various environmental conditions.

Check for signs of corrosion, damage or wear on the clamp and ensure the grounding conductor and support strand are clean and properly connected.