In overhead transmission lines, armor rod is crucial for preventing damage to the conductors. Armor rods have a helical design that makes it easier to insert different conductors. They are from materials like galvanized steel or aluminum alloy. These materials prolong the application equipment life and aid in preventing corrosion. Armor rods help to increase durability and provide mechanical stress protection. Its curved shape, strength restoration and affordability are a few of its many features. The efficiency, dependability and safety of overhead power transmission is from armor rods.

Decoding Armor Rod Material Choices

The choice of material for armor rods is dependent on several things. The chosen material must strive to offer materials that are appropriate and effective. The transmission lines have protection from the armor rods thanks to careful consideration of the circumstances. For advice on the best material to choose, it’s also a good idea to speak with experts in the field. The following are the elements that affect how decision making in light of the available information.

- Innovation – armor rods have improved strength due to the application of innovative technologies. These include like nanocomposites and smart coatings.

- Sustainability – take into account the effects of the armor rods manufacture, extraction of materials and disposal. For more sustainability, use eco-friendly products.

- Installation ease – choose armor rods made of an easy-to-work material, such as aluminum alloy. When making your choice, take into account the armor rods installation and maintenance costs.

- Mechanical stress – choose an armor rod with both flexibility and strength. The materials ought to be able to tolerate abrasive, compressive and bending loads.

- Environmental factors – check the local weather in the location where the armor rod installation will take place. The chosen material must be resistant to chemical pollutants and corrosion.

- Conductor material – the chosen rod needs to work well with the chosen conductor material. This will lessen the chance of galvanic corrosion and abrasion.

Online Communities and Experts for Armor Rod

Armor rod online communities help with the search for the precise knowledge and direction required. Some might involve knowledgeable exchanges that provide competent help with the application. To improve understanding, it’s also a good idea to take part in the communities and pose the appropriate questions. To be sure, it’s also a good idea to verify the correct information on the websites of the producers. These are the several armor rod community forums and expert interaction sites.

- Reddit is an engineering community where enthusiasts and professionals may talk about technological problems and their solutions. It is advisable to ask questions, exchanging experiences and gaining information from engineers and technicians.

- The Overhead Lines Working Group is an industry-specific forum where professionals in overhead line technology can assemble to discuss on ideal methods. They also aid in the exchange of new discoveries and difficulties about armor rods.

- Professionals working in the power transmission and distribution sector might find spaces in transmission and distribution communities, an online community. Their experiences and information about the use of armor rods are freely shared.

- Websites for manufacturers and suppliers These aids in comprehending the resources and technical details of armor rods. White papers, application manuals and technical support contact details are possible things they offer.

- Academic publications – to learn more about the technical details of armor rod technology, read published research papers and articles.

Futureproof Materials for Next-Gen Power Lines

The exact raw materials used to make armor rods vary depending on the kind of conductor they are to shield. It also relies on the particular conductor type and the armor rod’s intended use. Galvanized steel, aluminum clad steel and aluminum alloy are common materials used to make armor rods. To avoid abrasion, the material chosen for the armor rod should be like that of the conductor. These are the latest advancements in armor rod material.

- Nanocomposites – these are innovative material with improved durability and strength. Better defense against stress and exhaustion results from it. Additionally, they provide lighter armor rods that contribute to the transmission lines’ decreased weight.

- Real-time monitoring – this is possible due to smart coatings. This includes sensors and communication technology within the coating. Additionally, they enable analytical maintenance, which makes targeted replacements and repairs possible.

- Self-healing polymers – tiny breaks can self-repair since the armor rod’s materials contain self-healing polymers. These materials also improve the armor rod’s ability to withstand severe weather.

- Eco-friendly materials – these comprise substances like nacre or spider silk. They offer improved capacity for self-healing, flexibility and strength. Potential for more sustainable armor rod solutions exists with eco-friendly materials.

Technical specifications for armor rods

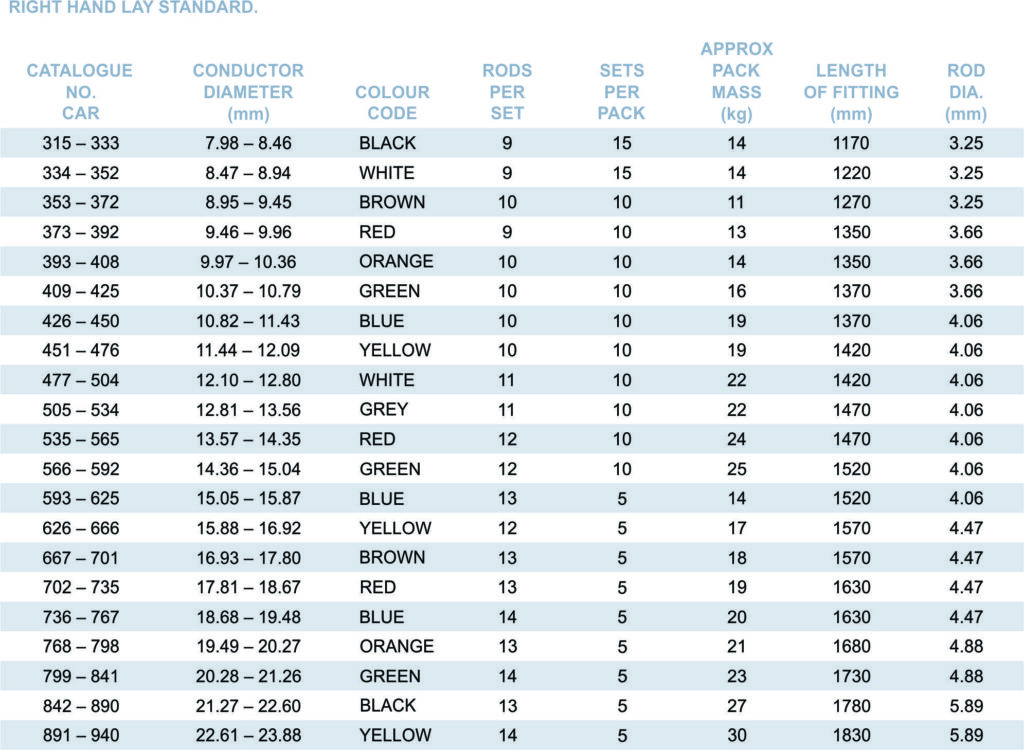

Armor rods come in a variety of styles, kinds, dimensions and forms. Each offers a unique set of advantages. To safeguard your application, review the armor rod technical parameters. It also contributes to safety and dependability. It’s also a good idea to get advice from experts in the field about the specs that work best for your application. The following are the main variables that affect armor rod technical parameters.

- Compatibility – verify that the chosen armor rod fits by checking the conductor type and diameter. This reduces the chance of slippage and abrasion.

- Design – examine the armor rod’s design, color coding and simplicity of crimping. This facilitates easier installation more quickly and improves compatibility with the armor rod.

- Temperature range – verify that the material of the armor rod can withstand the expected temperature range.

- Material specifications – verify the particular substance utilized in the armor rod. This makes your application more appropriate.

- Function – before choosing, be aware of the armor rod’s precise purpose. Select armor rods with features including strength, resistance to fatigue and ability to avoid flashover.

Navigating the Armor Rod Supplier Landscape

It may be difficult to find the ideal supplier in the market. Making the appropriate choice contributes to maintaining the overhead transmission cables dependability and quality. Depending on the requirements of your application, a variety of resources are available on the market to assist in finding the best vendors. It’s also a good idea to check with manufacturer websites, trade groups, industry journals, internet marketplaces and local and regional distributors. The following advice will assist you in selecting the ideal vendor or supplier.

- Costs and specifications – check the different costs among several vendors. Examine their products in relation to attributes like construction, durability and style.

- Supplier reputation – look for vendors who have experience and a track record in your particular area.

- Customer reviews – to learn more about the quality and service of various suppliers, look through internet reviews and industry suggestions.

- Standards and certifications – verify that the armor rods you’ve chosen adhere to the applicable industry certifications and standards. This aids in guaranteeing the applications and the armor rods quality and safety.

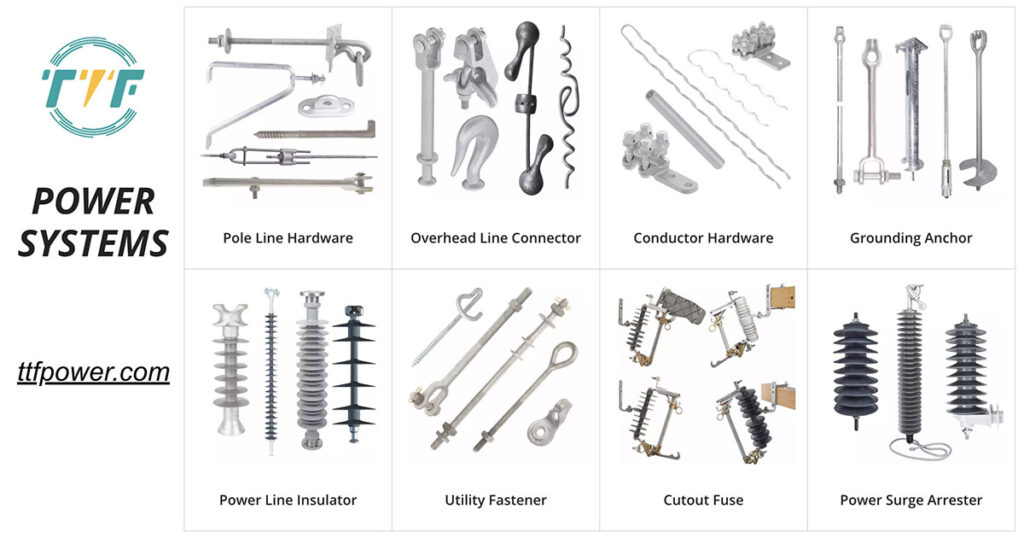

TTF Power Systems offers armor rods in a range of sizes, materials and functionalities. They offer a wide range of products at reasonable costs, as well as a global presence. Their armor rods are from a range of materials, sizes, types and special features. TTF Power Systems extensive experience in the power line industry allows them to ensure quality and dependability. Here are their contact details.

Website: https://ttfpower.com/

Catalog: https://ttfpower.com/about-us/

Landline (M-F, 9 am-6 pm): (+86) 22-8523-3528

Customer Service: support@ttfpower.com

Cutting-Edge Tech for Armor Rods

Many industry standards have established to use armor rods to change the electrical sector. Power grids now have increased safety, dependability and efficiency thanks to these developments. They also provide enhanced intelligence, strength and environmental awareness. Electrical systems have a more promising and sustainable future because to these trends. The numerous developments and trends in armor rods are as listed below.

- Recycled resources – reusing existing materials, such as steel or aluminum, can lessen their negative effects on the environment.

- Design – state-of-the-art computer simulations aid in the creation of armor rods that suit the conductor. This minimizes the rods stress areas and offers the greatest protection.

- Anti-vibration dampers – by using the rod’s dampening mechanisms, fatigue stress and vibration lessen. Additionally, this lengthens the life of the armor rod.

- Coatings – having ice-repellent qualities, known as anti-icing coatings. They lessen power outages brought on by ice accumulation on wires. This lessens the need for and expense of maintenance.

- Robotic installation – using robots to complete installations improves safety, productivity and encourages remote operations. These could consist of ground-based, climbing, and airborne robots.

- Advanced crimping materials – these comprise automated and intelligent crimping as well as the usage of self-locking crimp sleeves. This could help to guarantee reliable protection for the line and lower the possibility of human error.

Frequently asked questions

There are various types and designs of armor rods to select from for your applications. These include aluminum armor rods, composite armor rods, helical armor rods and dead-end armor rods.

There are various innovations and technology that poise the continued improvement of armor rods. These include technologies such as advanced materials, smart armor rods, robotic installation and eco-friendly solutions.

Inspections and maintenance of armor rods depend on factors such as type of armor rod, environmental conditions and specific requirements. It can be annually or semi-annually.