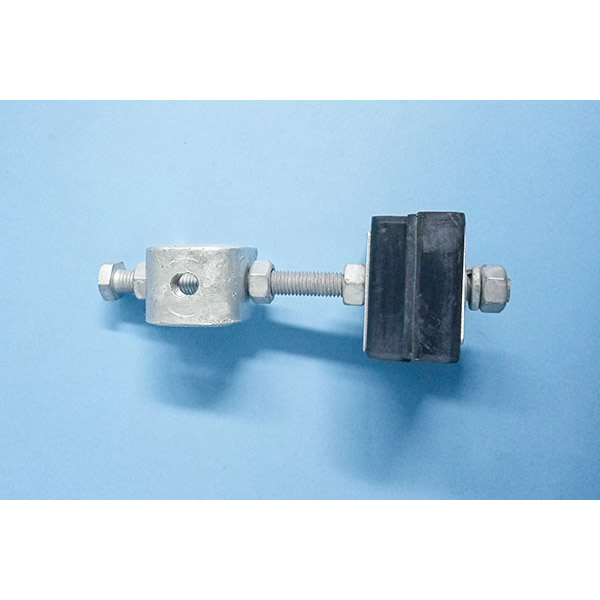

A downlead clamp is a device used to secure and guide overhead transmission lines. This is particularly the fiber optic cables that run down from the top of the structure. The clamps grip the cable to prevent movement or vibration. It is from a soft, durable material that cushions the cable and protects it from abrasion, wear and tear. Downlead clamps also help guide the cable along a specific path to ensure it does not come in contact with other objects. Various types of downlead clamps according to function include tower clamps, pole clamps, ADSS clamps and OPGW clamps. The clamps are from materials like stainless steel or galvanized steel. These materials provide strength and durability to the various applications. Advancements for downlead clamps may be material, design or manufacturing processes.

Benefits of using downlead clamp

Use of downlead clamps in the electrical installations provide several benefits to the applications. These benefits contribute to safety, reliability and efficiency. The clamps provide structural support and protection to cables in electrical installations. The following are the benefits of using downlead clamps.

- Installation best practices – use of clamps contributes to best practices for electrical installations. This ensures the installation meets industry standards, reduce the likelihood of various issues. It prevents issues like cable damage, electrical faults and system failures.

- Neat cable management – the clamps contribute to an organized and neat cable management system. This also enhances the aesthetics of the installation and makes it easier to identify and access cables.

- Cable strain prevention – use of downlead clamp prevents excessive strain on the cables. Strain can occur when the cables are not managed. Strain relief prevents cable damage and maintains the electrical systems lifespan.

- Electrical hazards prevention – the clamps feature insulating materials. These materials provide electrical insulation between the cables. This protects against electrical hazards like short circuits.

- Cable damage prevention – use of the clamps prevents physical damage to the cables. This ensures prevention of vibrations, winds or other forces.

- Cable separation – the clamps maintain proper separation between the cables. This reduces electromagnetic interference.

- Cable support – the clamps anchor cables in place to prevent them from sagging or movement. This ensures cable support, reduce the risk of damage and maintain the integrity of the electrical system.

- Durability – durability ensures the clamps maintain their functionality for long. This is because the clamps may face exposure to weather conditions such as moisture and UV radiation.

Types of downlead clamp according to function

There are various types and designs of downlead clamps to select from for your applications. Each type of clamps has various components and properties that contribute to their efficiency. Additionally, it is advisable to consult industry experts for guidance on the best clamp for your specific needs. The following are the common types of clamps according to functions.

- Pole clamps – these are clamps used on poles and are smaller and lighter than tower clamps.

- Tower clamps – these clamps have designs for use on tower. They are larger and more strong than other types of clamps.

- OPGW clamps – these are clamps designed for use with optical ground wire cables.

- ADSS clamps – these are clamps designed for use with All Dielectric Self-Supporting cables.

Industry advancements and updates for downlead clamps

There is continuing development of new technologies in the electrical industry. This is as the same in the industry for downlead clamp as we can see increased demands for stronger and safety transmission lines. new technologies aim to improve performance, reliability and efficiency of downlead clamps. The specific advancements vary depending on region, applications and industry regulations. The following are the common advancements for downlead clamps.

- Smart technologies integration – this includes integration of sensors and monitoring devices. They provide real-time data on clamp conditions. This may lead to predictive maintenance and improved reliability.

- Advanced coatings – new and improved coatings may enhance the durability and resistance of clamps. This is resistance to environmental factors reducing maintenance requirements.

- Customization – advancements could drive more customizable features to accommodate various cable types and sizes. This could make them adaptable to diverse applications in the industry.

- Safety features enhancements – this includes improved insulation properties or designs. They help reduce the risk of electrical hazards.

- Smart grid technologies – integration of the downlead clamps with the communication system enhances the role of the clamps in electrical grids. This also contributes to improved efficiency and reliability of the smart grid technologies.

- Material innovation – this includes new materials with improved properties. These include increased strength and enhanced corrosion resistance.

- Design – this may include design enhancements that optimize the functionality, ease of use and adaptability of downlead clamps.

- Environmental sustainability – this may include use of eco-friendly materials. It may also include processes that align with sustainable practices.

- Ease of installation – the features should aim to simplify the installation process, reduce time and labor costs during deployment.

- Durability – this includes development of clamps that are able to withstand extreme temperatures, vibrations or other challenging conditions.

Supplier and vendor information for downlead clamps

Finding the right downlead clamp supplier may be a challenging situation. This is especially with the current market. It is crucial to consider factors such as the specifications of the downlead clamps, certifications and compatibility. Also, check for customer reviews and ratings when available. This is to ensure the quality and reliability of the products. There are various ways to get suppliers as discussed below.

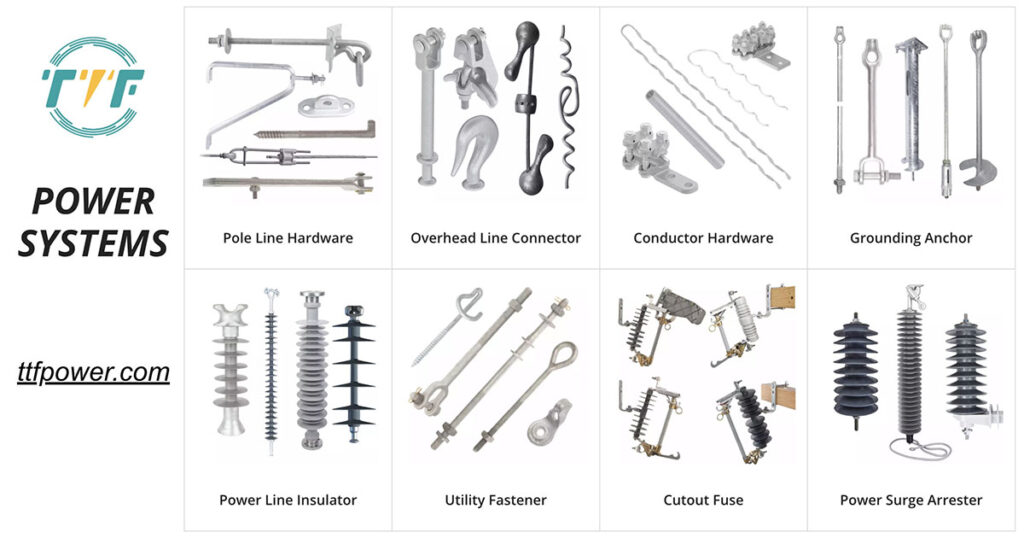

- Manufacturer websites – check the websites of the manufacturers that specialize in electrical hardware. This is because they provide product catalogs, specifications and contact information. Some manufacturers include TTF Power Systems.

- Online market places – this is a convenient way to discover a variety of downlead clamps from different suppliers. The available sellers may offer different products and product prices. Some of these places include Amazon, eBay and Alibaba.

- Electrical suppliers – check the reputation of electrical suppliers and distributors. They often carry a variety of electrical components including downlead clamps.

- Industrial suppliers – check the available suppliers in the industrial and electrical industry. They may offer a range of clamps suitable for a wide range of applications.

- Local electrical supply stores – check the local electrical supply stores that cater to contractors and electricians. They may carry a selection of downlead clamps and may place orders for you.

- Trade shows and exhibitions – attend industry trade shows or conferences related to electrical and industrial components. These events feature many suppliers providing an opportunity to explore different products.

- Consult with electrical contractors – checking with the electrical contractors may help with recommendations. This is dependin on their experience with specific suppliers and manufacturers.

TTF Power Systems if a one-stop-shop for utility pole hardware fittings and power line construction equipment. They provide the most extensive range of products in the electrical industry. They also offer excellent value and knowledgeable service. The company has various certifications to establish credibility and trust among clients. The following is their contact information.

Landline (M-F, 9 am-6 pm): (+86) 22-8523-3528

WhatsApp: (+86) 155-1086-4645

Cell Phone: (+86) 155-1086-4645

Customer Service: support@ttfpower.com

Community forums and expert interactions for downlead clamps

Community engagements and interactions are valuable when seeing information about downlead clamps. There are various online platforms for interactions that provide experts guidance you may need. Yet, it is advisable to verify the expertise and credentials of individuals providing advice. Additionally, it is advisable to provide relevant details about specific details about your application. The following are the various available community forums and expert interactions for downlead clamps.

- Electrician Talk forum – this is a forum for electricians and electrical professionals. They provide discussions on tools, equipment and specific components like downlead clamps.

- Reddit – the Electrical Engineering subreddit is a community where you can post questions, share knowledge and take part in discussions related to electrical engineering.

- Google groups – this includes the Sci.Electronics where electricians and electrical enthusiasts discuss various aspects of the electrical industry.

- Electrical Engineering Stack Exchange – this is a community-driven Q&A platform. You can ask and answer questions related to electrical engineering.

- LinkedIn groups – these include groups related to electrical engineering, power systems or industrial components. This is where you can take part in discussions, ask questions and connect with professionals in the field.

- The Electrical Forum – this is a community-driven forum where electricians and electrical enthusiasts discuss aspects of the electrical industry.

- Eng-Tips forum – this forum has a section dedicated to electric power and transmission where professionals discuss topics related to electrical components.

- Professional associations – explore relations related to electrical engineering such as the IEE.

Frequently asked questions

The latest advancements in material include the use of high-performance alloys, polymers or composite materials. These innovations aim to improve strength, corrosion resistance and durability.

There are advancements in smart technologies leading to downlead clamps with integrated sensors and monitoring capabilities. The smart clamps provide real-time data on factors like tension, temperature and environmental conditions.

Consider factors such as material properties, smart technology integration, certifications and compatibility with your specific application. Ensure the clamps meet industry standards and are suitable for environmental conditions of your installations.