In an electrical distribution system, drop wires get support and security by hardware called drop wire clamp. The conductors’ stability, correct spacing and prevention of sagging are all possible by the clamps. Drop wire clamps maintain the drop wire’s alignment and spacing by supporting its weight. Also, they aid in distributing strain along the entire length of the overhead lines. As a result, individual wires are safe from strain. Insulating materials may be present in some of the clamps. They shield other components from the drop wire’s electrical contact. They sustain effective power transmission while lowering the chance of disruptions and improving system reliability. Drop wire clamps are from robust, long-lasting materials like plastic or metal. They have a tightening mechanism that opens the drop wire clamp.

Designs of drop wire clamp

The clamps come in a variety of configurations to accommodate different components. The particular designs change based on some variables. These include the kind of supported cable, the setup specifications and the surrounding circumstances. It’s also a good idea to make sure the designs match the rest of your tools and equipment. The following characteristics are typical to drop wire clamp designs.

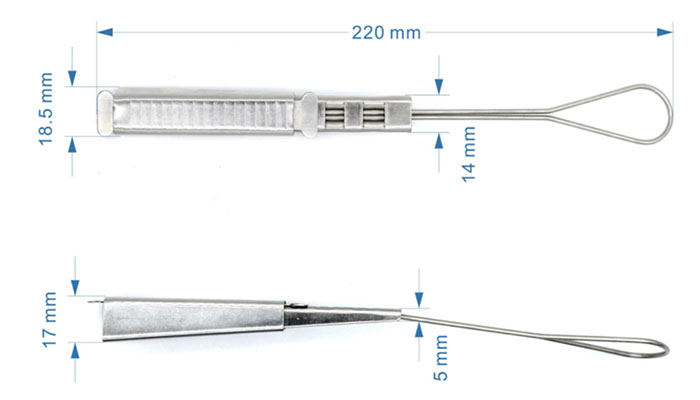

- Body – the primary component of the clamp that holds and fastens the cable in place is the body or frame. For durability, the frame is from aluminum or galvanized steel.

- Mechanism of attachment – the clamps have devices to hold the cables in place. Bolts, screws and other fasteners are examples of them. They guarantee a secure hold on the cable without harming it.

- Materials for insulation – materials for insulation work to keep the clamp and cable from coming into touch electrically.

- Hanger attachment – some clamps may have mechanisms that make it simple to fasten them to support structures.

- Weather protection – they have characteristics that guard against external influences. Among them are coatings that guarantee durability and dependable function resist corrosion.

- Adjustability – mechanisms have varying cable diameters several clamps feature adjustable components. This promotes a snug fit and appropriate support.

Applications for wire clamps

Applications for drop wire clamps are many and span many different sectors requiring the installation of aerial cables. Their goal is to guarantee the effective, dependable and safe functioning of aerial cable systems. Before choosing, it is also a good idea to examine the clamp’s characteristics and capabilities. The drop wire clamp can work in the following situations.

- Overhead power lines – drop wires and cables get support and security in overhead power lines by the clamps. This will guarantee accurate alignment and stop sagging.

- Cable television systems – drop wire clamps work in cable television systems to assist secure and organize the television cables.

- Television signals – drop wire clamps are a useful tool for managing and securing the cables that carry television signals to households and businesses in cable television networks.

- Urban and rural electrification – the clamps that fasten distribution cables ensure a dependable power supply for both urban and rural electrification.

- Electrified railway system – electricity for trains is from via overhead wires, which depend on support from the clamps.

- Aerial fiber network – drop wire clamps work in aerial fiber deployment to help secure and preserve the integrity of the fiber optic network.

- Communication cables – the cables work in the installation of communications cables. This is to give cables stability and support

- Street light systems – drop wire clamps are a useful tool in street lighting systems for supporting and organizing the cables that run the lights. This enhances the lighting system’s use and security.

- Industrial power distribution – in power distribution systems, the clamps hold and support the cables. This enhances the dependability and security of electrical systems.

- Renewable energy projects – they can work in the installation of overhead wires for transmitting power generated from wind turbines or solar panels. This guarantees a steady connection to the electrical grid.

Functions of drop wire clamps

Drop wire clamps work in a variety of sectors including overhead transmission lines. The overhead transmission systems depend on the clamps for functionality. They are thus a crucial part of the electrical grid. They guarantee the wires dependability, safety and security. The typical uses for drop wire clamps are as follows.

- Support and alignment – by giving cables support, the clamps stop them from sagging and guarantee correct alignment. This aids in preserving the efficiency and integrity of the overhead transmission networks.

- Preventing damage to the cable – the clamps stop swinging, which could cause abrasions or other problems. This is crucial when there is wind or other environmental difficulty.

- Weather resistance – corrosion-resistant materials and coatings work in the construction of the clamps. They can tolerate a range of weather conditions as well. This contributes to its long-term performance and durability.

- Load-bearing capacity – drop wire clamps work with a design and structure that can support a certain weight. This is to make sure they can sustain the cables’ weight.

- Tension distribution – the clamps aid in distributing tension along the wires’ whole length. This will shield individual wires from undue strain.

- Enhancement of stability – they also aid in maintaining the electrical distribution network’s stability. This lowers the possibility of cable movement-related interruptions.

- Installation ease – the clamps have mechanisms that make the operation easier and need less time to complete.

Drop wire clamp types

Drop wire clamps come in a variety of forms to suit various cable diameters, combinations and installation needs. For every use, there are variations in the designs and specifications of each type of clamp. It’s also a good idea to seek advice from industry experts on which type would be ideal for your particular requirements. The most popular kinds of drop wire clamps are as listed below.

- Wire wrap clamps – these clamps around the cable with a metal band screwed. They are appropriate for low-tension applications since they are straightforward and reasonably priced.

- Compression clamps – these clamps provide pressure to the cable by tightening a wedge that fits into the clamp. They are appropriate for greater tension applications and offer a more stable grip.

- Suspension drop wire cables – cables can suspend from a support structure using a suspension drop wire clamp. They operate in overhead transmission networks with hangers.

- Insulated drop wire clamp – these clamps use materials that don’t conduct electricity to keep the clamp and the clamp.

- Parallel groove drop wire – the cable stays in place by the parallel groove in this clamp. This keeps the cable from moving and offers stability.

- Corrosion-resistant – the drop wire clamp is from corrosion-resistant materials or coatings. Additionally, it is perfect for installations in places with harsh environmental conditions.

- Adjustable drop wire clamps – these clamps may face adjustments to fit various cable sizes. They provide flexibility system needs and cable size.

- Hanger drop wire clamps – cables can attach to hangers or support structures using the hanger drop wire clamp designs. This makes it possible for cables in overhead transmission systems to be in position.

- Strain drop wire clamps – the tension in the cables depend on the strain drop wire clamp design for management. This guarantees the cables’ integrity under different loads.

The drop wire clamp’s characteristics

Drop wire clamps are effective in transmission lines because of some properties. The drop wire clamps share the following characteristics in common.

- Design – they contain methods for securing wires that are easy to use and straightforward, making installation easier.

- Resistance to corrosion – the clamps get shield from rust by coatings that are resistant to corrosion.

- Load bearing capacity – drop wire clamps have a load bearing capacity that allows them to withstand particular loads and tensions. They make sure they can sustain the wires’ weight.

- Cost-effectiveness – they are from affordable resources and production techniques. They provide a fair mix between price and functionality.

- Weather resistance – the clamps comprise of a weather-resistant and long-lasting substance. The materials can resist changes in the environment.

- Adjustability – they are able to accommodate a range of cable sizes with flexibility. They aid in guaranteeing a snug fit.

- Insulating qualities – to avoid electrical contact between cables, the clamps additionally use insulating materials. This lowers the possibility of short circuits.

Frequently asked questions

A drop wire is a component used to support and secure drop wires to cables. This helps to prevent sagging and ensuring the stability of the electrical distribution network.

Drop wire clamps are from durable material such as galvanized steel or aluminum to withstand environmental conditions and ensure long-lasting performance.

Insulated drop wire clamps incorporate materials to prevent electrical contact between the clamp and the cable. This reduces the risk of short circuits and enhancing overall safety.