A guy clamp is a type of hardware used to secure guy wires or cables to utility poles and transmission lines. Guy wire is a tensioned cable anchored to the ground at one end and attached to the structure they support. Guy clamps securely fasten the guy wire to the pole without damaging the wire. They ensure the stability and safety of utility poles, towers and other structures. Guy clamps are from durable materials that resist rust and corrosion. These materials include stainless steel, aluminum or galvanized steel. These materials elevate the performance of the transmission lines in South America. Common examples include thimble clamps, bolted guy clamps, anchor rod clamps and swage guy clamps. They find use in applications such as utility poles, transmission towers, telecommunication towers, suspension bridges, marine rigging, guyed masts and agriculture.

Key features of guy clamp

Guy clamps has various features that help them ensure the stability and security of the various structures. The specific features vary depending on the application and requirement of the clamps. The following are the key features of the guy clamps.

- Customization – customization options allow clients to specify dimensions, materials and design features to meet specific requirements.

- Anti-vibration – this feature helps to dampen vibrations and reduce the transmission of oscillations along guy wires.

- Load bearing capacity – the clamps are capable of supporting the tension and load applied by the guy wire without failure.

- Durability – they are able to withstand the environmental conditions which they should hold. They are able to resist corrosion, weathering and wear and tear.

- Tension adjustability – they also offer the ability to adjust tension in the guy wires. This helps to maintain the required tension levels.

- Ease of installation – the clamps have the designs for easy installation with tools for assembly and tensioning.

- Materials – the clamp is from durable and corrosion resistant materials.

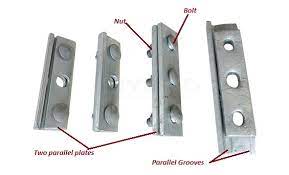

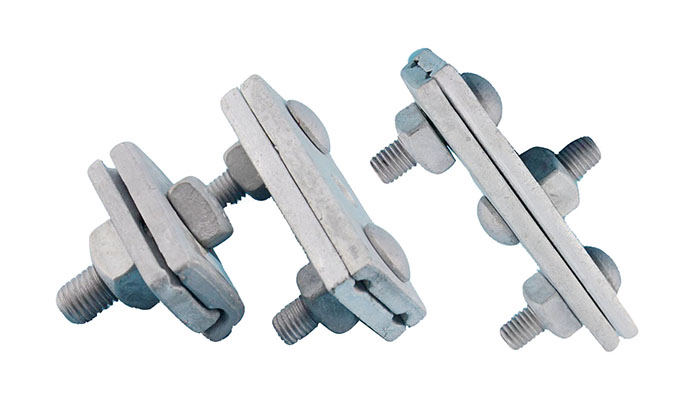

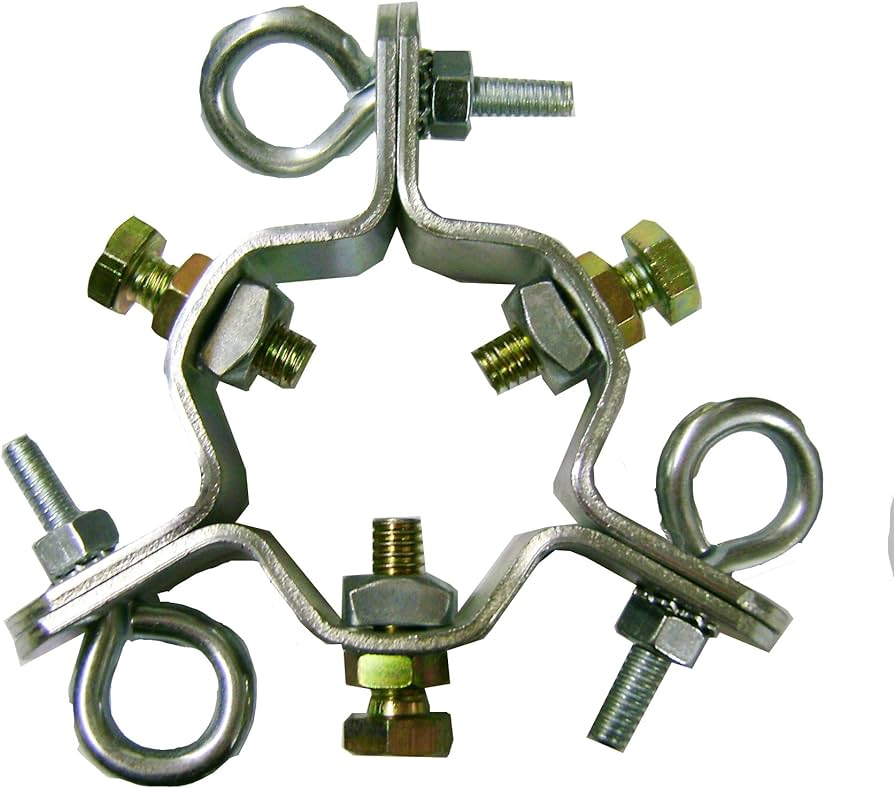

- Design – there are various designs and sizes that accommodate different wire or cable diameters. Common designs include thimble clamps, bolted clamps and wedge clamps.

- Secure cable attachment – they have designs that securely hold the guy wire to prevent slippage or loosening. They may feature grooves or channels that match the wires diameter to ensure a secure fit.

Selection and installation of guy clamp

The selection of guy clamps is a critical process for success of various applications. It includes considering various factors that ensure stability and safety of structures supported. These factors include application type, wire diameter, load requirements, environmental conditions, ease of adjustment, material, durability and load distribution. The installation process should ensure stability and safety of structures supported by guy wires. Additionally, it is advisable to consult with industry experts for guidance on the installation whenever in doubt. The following is a step-by-step installation process of guy clamps.

- Preparation – gather all the necessary tools required for the installation. This is including guy clamps, guy wire, wrenches, measuring tape, wire cutters, tension and safety equipment. Ensure the anchor point is securely in place and suitable for the intended application.

- Guy clamp positioning – position the clamp on the guy wire at the desired location along the length.

- Slip the guy wire into the clamp – insert the guy wire into the groove of the clamp ensuring it is fully seated and secure within the groove.

- Secure the clamp – use the suitable tools to secure the clamp in place depending on the type of clamps used.

- Tighten to the required tension – use a measuring device to achieve the correct tension.

- Trim excess wire – use wire cutters to trim the excess wire leaving only the necessary length for anchoring.

- Final inspection – inspect the installation to ensure that guy clamp is securely fastened and the guy wire correctly tensioned.

- Documentation – keep detailed records of the installation. This includes the tension applied, installation date and any other relevant information.

Maintenance and inspection of guy clamp

Maintenance and inspection of guy clamps ensures the continued stability and safety of structures supported. It also helps to identify issues and prevent potential failures. This helps to extend the lifespan of the supported structures and reduce the risks of accidents. Additionally, it is advisable to perform professional maintenance and inspection for the guaranteed success. The following is a basic guide for maintenance and inspection of guy clamps.

- Regularly inspect all the guy clamps for visible signs of damage, corrosion or wear. Check for cracks, rust or deformation in the clamps.

- Check all the nuts, bolts and other fasteners are securely tightened to maintain the integrity of the installation.

- Ensure the guy wire remains properly tensioned and correctly aligned and verify there is no slack.

- Examine the clamps and the guy wire for signs of corrosion or rust. This is especially in environmental with exposure to moisture, salt or harsh chemicals.

- Assess the impact of environmental factors such as wind, humidity and exposure to chemicals.

- Regularly clean the clamps and guy wires to remove dirt, debris and potential contaminants.

- Apply anti-corrosion coatings or lubricants to the clamps and wires to help protect against rust and corrosion.

- Replace the clamps with signs of significant damage, wear or deterioration.

- Maintain detailed records of the inspections and maintenance to help keep track of the condition of the installation.

Comparative analysis of guy clamp in South America

A comparative analysis of guy clamps includes assessing and evaluating the usage, challenges and trends in the region. Usage in south America depends on the utility infrastructure, renewable energy and telecommunications. It also involves assessing the trends in material, anti-corrosion technologies and customization. Additionally, you should consider the different brands and manufacturers available in the market. The following are the common factors to include in a comparative analysis for the guy clamps.

- Usage and applications – guy clamps find use in various applications. This is including utility infrastructure, renewable energy, telecommunications and maritime and offshore. Assess how the clamps enhance stability and security in each of the application area.

- Trends and innovation – the various advancements in guy clamps include material advancements, anti-corrosion technologies, customization and remote monitoring. Evaluating the effectiveness of these factors in meeting the sustainability of the application.

- Challenges – assess the various challenges that meet the use of guy clamps in south America. The region has a range of challenges which include environmental conditions, seismic activity and regulatory variations. Assess how the type of guy clamp withstands the various challenges in the region.

Certifications and standards in South America

There are various certifications and standards of the guy wire in south American countries. These standards vary depending on the specific application, industry and country in which the clamps will install. They help to ensure the quality and safety of the guy clamps in the region. Some of the south American countries adopt to international standards and certifications. The following are the common standards and certifications for guy clamps in south America.

- ASTM standards – these are international standards for design and materials of the guy clamps.

- ABNT standards – these are national standards for Brazil that govern various products. This is including hardware and construction materials.

- INMETRO standards – this is responsible for regulating product safety and quality of guy clamps.

- Industry-specific standards – each industry has various industry specific standards that apply to guy clamps.

- International standards – these standards for global industries and electrical components.

- Local regulations – each south American country has a set of their national standards and regulations. Manufacturers and users must adhere to these local regulations if applicable.

Regional market for guy clamps in South America

There are various factors that influence the regional market for guy clamps in South America. Some of these factors include economic growth, infrastructure development and specific needs of different industries. Manufacturers and suppliers should assess these factors to enhance their success in the market. The following are the factors that shape the regional market for guy clamps in South America.

- Utility infrastructure – this sector relies on the guy clamps to stabilize the poles and towers. Investments in expanding and upgrading the electrical grids drive the demand for guy clamps in the sector.

- Telecommunication – the installation of cell towers, broadcasting antennas and communication equipment drives the demand for the clamps.

- Renewable energy – the clamps help to secure wind turbines and solar panels structures in renewable energy sector.

- Construction and infrastructure – the growth of the construction industry contributes to the demand for guy clamps.

- Agriculture – agriculture relies on the trellises and support structures for vineyards and agricultural machinery. Guy clamps help to support some of these structures.

- Railway electrification – the industry depends on guy clamps to support overhead lines in electrification systems.