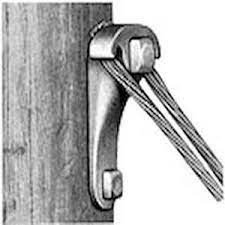

A guy hook is a hardware used to support and anchor utility poles to maintain their stability. it mainly helps to attach guy wires to overhead transmission poles. It also helps prevent them from leaning or collapsing from the overload. Guy hooks are available in various types, sizes and designs to accommodate different transmission line structures. They are from materials such as malleable iron and stainless steel. Guy hooks are essential in the construction and maintenance of overhead transmission lines in South America. Examples of guy hooks include double headed, single headed, pressed steel, malleable iron and anchor guy hooks. They find use in applications such as transmission lines, telecommunication, wind turbines, lighting poles and structural support.

Key features of guy hook

The availability of these features depends on the design, type and intended use of the guy hook. Each of these features help to ensure proper stability and support of the overhead transmission lines. In addition, it is advisable to consult industry experts to select the guy hooks that best suits your application. The following are the key features of the guy hooks.

- Design – guy hooks are available in different designs which helps to meet the different requirements of applications.

- Corrosion resistance – guy hooks are from materials that resist the high humidity and saltwater exposure.

- Thimble attachment – some of the guy hooks have a thimble fitting at the attachment point. It helps to protect the guy wire from wear and provide a smooth surface for the wire to wrap around.

- Customization – customization allows the guy hook to meet specific installation needs.

- Durability – they have a design that is able to withstand the different rigors of the environment.

- Material – they are from materials that offer strength and corrosion resistance such as steel and iron.

- Size and load capacity – the availability of different sizes and load capacities help to handle the expected tension and load.

- Threaded ends – threaded ends help to screw into the ground for secure anchoring especially for rocky or hard soils.

- Ease of installation – guy hooks may feature pre-drilled holes for easy attachment of guy wires.

Selection and maintenance of guy hook

The selection process of guy hooks includes considering several factors that influence the effectiveness of the hardware. These factors include environmental conditions, corrosion resistance, size and type, cost effectiveness and maintenance and inspection. The installation involves attaching the guy wire to a utility pole to provide stability. Also, it is advisable to seek professional guidance whenever in doubt about the installation process. The following is a step-by-step installation process of the guy hook.

- Preparation – gather all the necessary tools required for the installation. These include guy hooks, guy wire, fasteners, wrenches, thimble, measuring tape and safety equipment.

- Site assessment – assess the installation area and ensure the guy hook positions at the correct height on the utility pole.

- Guy wire preparation – attach the thimble to the end of the guy wire to provide a smooth surface for wire wrapping.

- Guy hook attachment – place the guy hook on the pole at the suitable height. Use fasteners to secure the guy hook to the surface.

- Guy wire wrapping – wrap the free end of the guy wire around the guy hook. This depends on the type of guy hook and the specific requirements of the installation.

- Secure the guy wire – use wrenches to tighten the guy wire around the guy hook. Ensure it is tightly secured to the hook and there is sufficient tension.

- Guy wire tensioning – apply the desired tension to the guy wires to stabilize the structure.

- Check alignment – use a measuring tape to ensure the guy wire aligns correctly and no excessive sagging.

- Anchoring – follow the specific anchoring procedures if applicable. This involves using anchor rods, ground anchors and other materials.

- Final inspection – inspect the guy hook, guy wire and other installations to ensure secure connections.

Maintenance and inspection of guy hook

South America has diverse weather and environmental conditions that may influence performance of guy hooks. Maintenance and inspection ensure the safety and reliability of overhead transmission lines. The frequency also depends on the environmental conditions in the installation area. Additionally, it helps identify and address potential issues before they cause failures. The following is a basic guide to the maintenance and inspection of guy hook in South America.

- Establish a regular maintenance and inspection routine for the guy hooks. This depends on the location and environmental conditions.

- Visually inspect the guy hooks to check for signs of wear, corrosion, deformation or damage.

- Examine the guy hooks for signs of rust or corrosion especially in coastal and tropical areas. Apply the required coatings to help reduce the effects of corrosion.

- Check the tension of the guy wire to ensure it maintains the required level of support. Also, inspect the alignment of the guy wire to ensure proper positioning.

- Ensure all the fasteners are tight and in good condition t increase the integrity of the installation.

- Examine the structural integrity of the guy hook and check for cracks, fractures or deformation.

- Replace any guy hooks that shows signs of wear, damage or corrosion to prevent potential safety hazards.

- Keep detailed records of the inspections including dates and findings. This helps to track the condition of the guy hooks.

Comparative analysis of guy hooks in South America

A comparative analysis includes evaluating and assessing different types, materials and features of guy hooks. This helps to determine the best suited for the various applications. It also includes assessing the different brands, suppliers and manufacturers of guy hooks in the market. Additionally, it is advisable to consult with local experts and engineers to help make an informed decision. The following are the factors to include in the comparative analysis in South America.

- Ease of installation – consider the ease of installation especially for complex installations.

- Local availability – assess the availability of local manufacturers and suppliers in the region. This is because they affect the lead times and project logistics.

- Maintenance and inspection – consider the ease of maintenance, inspection and replacement. This is especially in regions that can speed up wear and corrosion.

- Environmental conditions – south American countries have high humidity, coastal areas and exposure to salt. The selected guy hooks should withstand these factors.

- Type – there are various designs and types of guy hooks to select from. Consider the type and material used to manufacture the guy hook.

- Load capacity – the load capacities of the guy hook should match the specific requirements of the application.

- Cost effectiveness – consider the cost and balance the quality with budget constraints when choosing guy hooks.

- Customization – check for customization features of the selected guy wire. This helps to make the guy hooks meet the specific project requirements.

Certifications and standards in South America

These certifications and standards influence the use of guy hooks in South America. They help to ensure the quality, safety and performance of guy hooks in the region. Also, it is advisable to ensure the selected guy hooks meets the relevant standards and regulations. The following are the common certifications and standards of guy hooks in South America.

- ANSI standards – these are American standards for pole line hardware including guy hooks.

- IEC standards – these are standards for insulators used in overhead transmission lines.

- ISO certification – the ISO standards ensure the quality of materials and manufacturing processes for guy hooks.

- ASTM standards – these are standards referenced for materials and testing procedures in the region.

- Local standards and regulations – each South American country has their own set of standards and regulations that apply to guy hooks.

Regional market for guy hooks in South America

There are various factors and trends that affect the regional market for guy hooks in South America. It also depends on the varying conditions and requirements in different countries and regions. The market conditions also change over time depending on economic factors, government policies and industry developments. The following are the factors that influence the regional market for guy hooks in south America.

- Competition – the presence of both local and international manufacturers offers a range of guy hooks with different features.

- Replacement market – older guy hooks and utility poles require maintenance and upgrades. This is to meet the current safety and performance standards.

- Export opportunities – the south American countries may export guy hooks to the neighbouring countries. This influences the demand and supply of guy hooks in the market.

- Energy sector – investments in power generation, transmission and distribution ensures a reliable power supply.

- Renewable energy – guy hooks help to support wind turbine towers and solar panel structures in renewable energy projects.

Frequently asked questions

There are various types and designs available in the construction of transmission and telecommunications in South America. These types include screw-in guy hooks, U-bolt guy hooks and clevis guy hooks.

Guy hooks offer several benefits to various applications in South America. These benefits include increased stability, improved safety, extended lifespan and reduced maintenance costs.

There are a few challenges to using guy hooks n south American countries. These challenges include corrosion, theft, environmental impact and availability of maintenance.