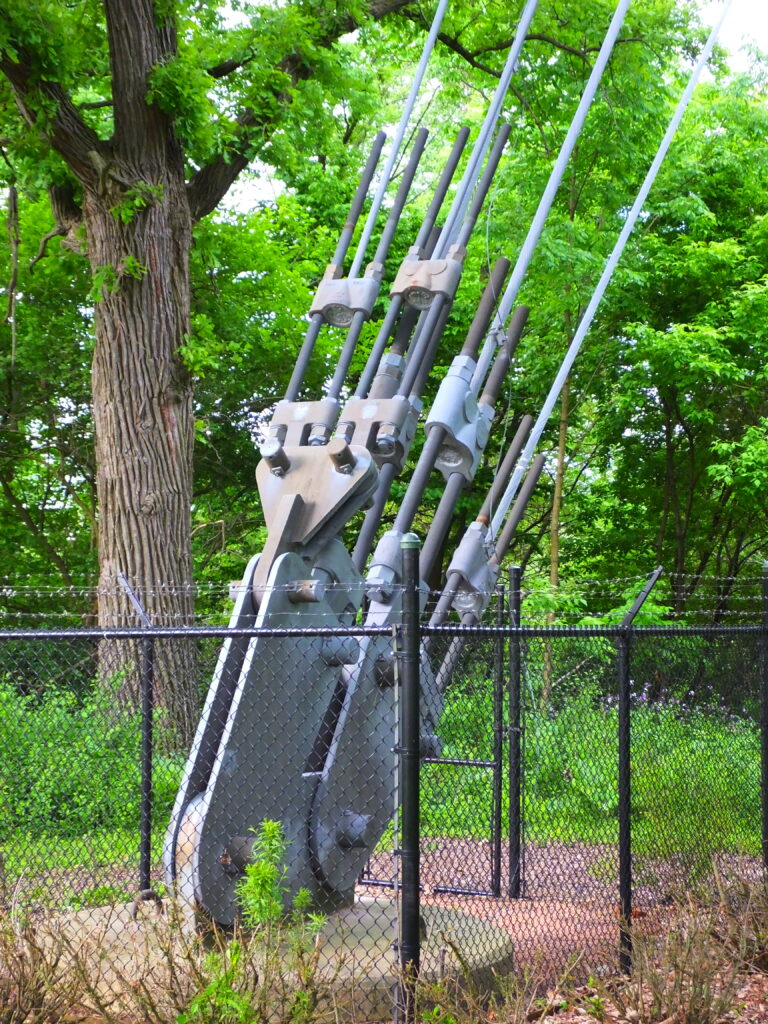

A guy anchor is a component used to support and stabilize utility poles to maintain the structural integrity. It consists of a steel rod or cable that is securely anchored into the ground at an angle away from the pole. The tension formed by the anchor helps to offset the adjacent forces and wind loads that affects the pole. A guy anchor mainly works in soft, hilly terrain or areas prone to high winds. The installation of the anchors should ensure the stability and safety of the transmission line. Guy anchors are from durable materials like steel. This helps them to withstand diverse terrains and climatic conditions of South America. Examples include deadman anchor, screw anchor, plate anchor, concrete anchor and spike anchor. They find use in applications such as utility poles, transmission towers, antenna, masts and agriculture.

Key features of guy anchor

The guy anchors have various features that help provide stability and support to various structures. The features vary depending on the specific application and engineering requirements of the project. The following are the main features of the guy anchor.

- Design – guy anchors have a design capable to withstand the tensile forces generated by the structure supported.

- Size and length – the size and length of the guy anchor depend on the specific application and expected load.

- Tensioning mechanisms – a tensioning mechanisms that help to adjust the tension in the guy wires. These mechanisms include turnbuckle or tensioning devices.

- Load capacity – guy anchors have load capacities to ensure they can support the intended weight or force.

- Environmental considerations – the anchors should account for the environmental conditions in the installation area. They deal with sandy soils, rocky terrain or extreme weather conditions.

- Compatibility – the anchors should be compatible with the structure they support and type of cables used. Proper compatibility ensures efficient installation and reliable performance.

- Material – they are from durable materials like steel to help withstand environmental conditions.

- Installation – they are easy to install using various methods which including in concrete, screwing into the ground and attaching to the structure itself.

Selection and installation of guy anchor

The selection of guy anchors includes considering various factors to ensure the anchor provides support and stability. These factors include site assessment, load requirements, anchor type, materials, installation method and tensioning mechanisms. The installation should provide stability and support to structures like utility poles, towers and vertical installations. Additionally, it is important to note that the installation process varies depending on the type of guy anchor, site conditions and the specific requirements of the project. The following is the basic installation process of the guy anchor.

- Site preparation – conduct a site assessment to understand the soil conditions, terrain and other factors. Ensure the area is clear of any obstructions, debris or vegetation.

- Anchor selection – select the appropriate type of guy anchor based on the site conditions, load requirements and recommendations.

- Marking and layout – mark the exact location where the anchor will install using a marker. Lay out the anchor considering angle of attachment, distance from the structure and length of the anchor.

- Excavation – excavate a hole or trench for the anchor depending on the soil conditions and engineering recommendations.

- Anchor installation – the installation of the anchor includes use of various methods. These include embedding in concrete, screw anchors, drilled shaft anchors and plate anchors.

- Tensioning and adjustment – tension the guy wires or cables using the suitable tensioning mechanisms. This helps to ensure the anchor provides the necessary support.

- Backfill – backfill the hole with soil ensuring proper compaction.

- Surface restoration – restore the surface of the installation site to its original condition.

- Inspection – conduct inspections and testing to ensure the anchor is properly installed and provides maximum stability.

- Documentation – keep detailed records of the installation process. This includes any adjustments made and the anchors location for future reference.

Maintenance and inspection of guy anchors in South America

Proper maintenance and inspection of the guy anchors ensure the continued stability and reliability of the structures. It also helps identify and address issues that could lead to dangers and accidents. The frequency of this process varies depending on the environmental conditions and installation. Additionally, you should perform professional inspection and maintenance once in a while for the continued performance. The following is a basic maintenance and inspection of the guy anchors in south America.

- Develop a regular maintenance schedule based on industry standards and recommendations.

- Conduct regular visual inspections to look for any signs of damage, corrosion, wear or loose hardware.

- Check the condition of the soil around the anchor and look for signs of erosion, settling and soil washout.

- Use tension meters to ensure that the guy wires maintain the required tenson as recommended. Ensure the anchor angle and position remains as intended.

- Inspect the anchor and its components for signs of corrosion or rust and prevent downtime.

- Apply proper lubrication to prevent corrosion and maintain functionality to the moving parts.

- Periodically test the soils to assess the soils bearing capacity and the anchor’s performance. This helps identify any issues related to the anchors’ stability.

- Keep detailed records of inspection findings and any maintenance done.

Comparative analysis of guy anchor in South America

A comparative analysis includes assessing and evaluating various factors specific to the needs and conditions. South America has a diverse range of geography including soil types, environmental factors and infrastructure needs. These factors help to make a decision about the type, design and maintenance requirements of the anchors. Additionally, it is advisable to consult with industry professionals for guidance on the best guy anchors. The following are the key factors to include in the comparative analysis.

- Soil types – south America has a wide range of soil types to consider. These include clay, sandy and rocky soils. The selected guy anchor should suit the specific soil condition of each location.

- Cost and budget constraints – the cost of guy anchors and installation varies depending on the type of anchor location.

- Local expertise and labor – the availability of skilled labor and local expertise in the installation and maintenance of guy anchors.

- Corrosion resistance – the guy anchors should be corrosion resistant to various environmental conditions.

- Infrastructure needs – the growth of rural and urban areas require the use of guy anchors to support the various towers.

- Load requirements – the load requirements of guy anchors depend on the specific infrastructure they support.

- Long-term maintenance – consider the ease of maintenance and availability of maintenance resources.

- Future expansion – consider the potential for future expansion or increased loads on the supported structures.

- Environmental conditions – the guy anchors should withstand the various environmental conditions in South America. These conditions include heavy rainfall, high winds and earthquakes.

Certifications and standards in South America

South American countries has various certifications and standards that govern the use of guy anchors. Each of the country has their own set of standards and some adopt the international ones. Also, it is advisable to ensure the selected guy anchors comply to the relevant industry standards. The following are the common standards and certifications in South America.

- ISO certifications – this are standards for a quality management system for guy anchors.

- ASTM international – this is a standard specification for anchor plates, embeds, pigtail connectors and anchor rods.

- European Norm standards – some countries adopt the European standards for certain products including the anchor systems.

- Local and national standards – these are local standards and regulations governing the use of guy anchors.

- ANSI standards – these are standards that cover the design, fabrication and installation of guy anchors.

- IEC standards – these are standards that provide international standards for electrical and electronic equipment.

- Local building codes – local building codes and regulations stipulate the use of specific standards.

- Environmental regulations – these regulations may impact the use of anchors especially in sensitive ecosystems.

Regional market for guy anchors in South America

There are various factors that influence the regional market in South America. This is from the diverse levels of industrialization in south America. These includes factors like economic conditions, population growth, urbanization and infrastructure investments. Also, it is advisable for manufacturers to assess these factors for their guaranteed success. The following are the factors that influence the regional market for guy anchors.

- Renewable energy – the development of renewable energy in the region influences the availability of guy anchors.

- Economic growth – the development and growth of economies influence the demand and supply of guy anchors.

- Infrastructure development – the need for reliable electricity transmission influences the demand for guy anchors. They help to support the various infrastructure required for the development.

- Population growth – the growth in population increases the demand for reliable electricity transmission. This increases the need for the anchors and need for support and stability.

Frequently asked questions

A guy anchor is a component used to provide stability and support to supporting structures. These structures include towers, poles and buildings. It helps to provide support to various applications in south America that lead to the reliable energy transmission.

South America has a wide range of soil conditions and environmental conditions that influence the demand for guy anchors. These include screw anchors, plate anchors, concrete anchor and drilled shaft anchor. They should resist corrosion and provide maximum stability.