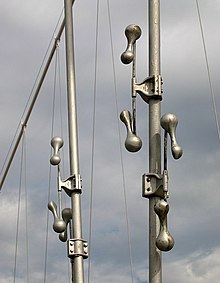

A spiral vibration damper is a device used to reduce vibration and stress on overhead conductors. It is also known as a Stockbridge damper or as an SVD. It consists of a helical coil made of a flexible material such as aluminum or steel. The coil attaches to the conductor and acts as tuned mass damper. The spiral damper absorbs some of the kinetic energy to dampen the oscillations and reduce stress on conductors. Its spiral design allows for flexibility and adaptability to different conductor sizes and types. Reduced vibration prevents fatigue and improves the reliability of the electrical system. Common types of SVD include helical dampers, spacer dampers, preformed dampers and yarn dampers.

Selection process of spiral vibration damper

Spiral vibration dampers come in a variety of designs from different manufacturers. As a result, selecting the ideal dampers for your projects might be time-consuming. When choosing the best dampers for your installation, keep the following points in mind.

- Power line specification – assess the specific characteristics of the power line. This is including conductor size, tension levels, span length and anticipated wind conditions.

- Vibration analysis – conduct a thorough vibration analysis of the power line. This is to identify the frequencies and amplitudes of the wind-induced vibrations.

- Manufacturer’s record track – select vibration dampers from manufacturers with a good reputation. This should also involve experience and expertise in power line projects.

- Standards compliance – ensure that the selected dampers follow the relevant industry standards and specifications.

- Damping performance – check the damping performance of the dampers. This is by considering factors such as the effectiveness of vibration reduction, design and damping materials.

- Durability and maintenance – consider the durability and maintenance requirements of the dampers. You should look for dampers made from materials that withstand environmental conditions. These includes factors like UV exposure, temperature variations and corrosive elements.

- Cost – check the cost effectiveness of the dampers by comparing the costs of different damper options. Check on the performance, durability and long-term maintenance requirements.

- Technical support – ensure that the manufacturer offers adequate technical support. This includes help with damper selection, engineering calculations, installation guides among others.

How to safely install spiral vibration damper

The spiral vibration damper installation procedure is reliant upon the type of damper, manufacturer guidelines and project specifications. SVD installation should be under the manufacturer’s instructions and after consulting with knowledgeable experts. This guarantees that wind-induced vibrations on electricity cables are properly controlled. The installation procedure for the dampers breaks down into steps below.

- Preparation – conduct assessment of the application before the installation. This is to determine the optimal locations for their placement along the power line. This should consider factors like conductor type, span, wind conditions and the desired level of vibration damping.

- Conductor preparation – clean the surface of the conductor to remove any dirt, grease or other contaminants. Check the conductor for signs of damage or defects that may affect the installation.

- Positioning – determine the location for installing the SVD along the length of the conductor. Consider factors such as conductor sag, span length and environmental conditions.

- Attachment – attach the SVD to the conductor according to the manufacturer’s recommendations. Ensure proper alignment and fastening to the conductor.

- Tensioning – adjust the tension according to the manufacturer’s specifications. This is through the use of the tensioning tools.

- Inspection – inspect the installed damper to ensure it positions and attaches to the conductor. Check for signs of damage or defects that may affect the performance of the damper. Ensure there are no safety hazards or issues that could affect the performance of the dampers.

- Maintenance – follow the manufacturers recommendation for ongoing maintenance of the spiral vibration dampers. This is including the periodic inspections and any replacements or adjustments.

- Documentation – keep records of the installation process including locations, installation date and observations.

Maintenance practices for spiral vibration dampers

Spiral vibration dampers’ continuous efficacy in reducing aeolian vibrations depends on routine maintenance. The installation region’s varied environmental variables determine how the activity occurs. Propre maintenance of the SVD ensures the continued effectiveness in reducing vibrations. It’s also a good idea to speak with experts in the field sometimes. An overview of spiral vibration damper maintenance is as provided below.

- Conduct regular inspections of the spiral vibration dampers to check for any visible signs of damage, wear or corrosion. Check to ensure the dampers are securely attached to the conductors.

- Clean the surface of the dampers to remove dirt, dust or debris accumulated overtime. Use a soft brush or cloth to wipe the dirt.

- Check the tension to ensure it remans within the recommended range. Use a tensioning tool to measure and adjust the tension as needed.

- Ensure fasteners, bolts, or clamps are in good condition and properly tightened.

- Assess the condition of the coating looking for any areas where the coating may lead to corrosion.

- Confirm the adjustable features are set according to the environmental conditions. Adjust if necessary to optimize the dampers performance.

- Replace or repair anu worn out dampers to maintain optimal performance. Follow the manufacturers recommendations for repairing damaged dampers.

- Consider environmental conditions at the installation site to prevent corrosion from various elements.

- Perform emergency inspections after severe weather events like storms or high winds. This is to check for potential damage.

- Keep detailed records of each inspection including maintenance activities performed and observations made.

Testing for Stockbridge dampers

Testing for spiral vibration dampers involves assessing their performance in reducing conductor vibrations. It also helps to improve the reliability of overhead transmission lines. Additionally, it is important to conduct testing and analysis to check the performance, reliability and effectiveness of the dampers. This helps to make informed decision on design, placement and system performance. The following are testing methods for spiral vibration dampers.

- Field testing – this involves installing dampers on actual transmission lines and monitoring their performance. Track the behavior of the transmission line during windy conditions to check the effectiveness of the dampers.

- Fatigue testing – this involves putting the dampers to repeated loading cycles to check their durability and performance. Assess the factors such as material fatigue strength, endurance limit and fatigue crack broadcast.

- Quality control testing – install quality control testing during the manufacturing process. This helps to ensure the dampers meet performance standards. Use destructive and non-destructive testing methods to verify material properties, dimensions and mechanical properties.

- Laboratory testing – this allows for controlled experiments to check the performance of the damper. Measure factors such as natural frequency, damping ratio and resonance behavior.

- Comparative studies – conduct comparative studies between transmission lines with and without the dampers. This is to assess their impact on system reliability and performance. Compare factors such as conductor vibration levels, maintenance requirements and outage rates.

Certifications for spiral vibration dampers

Certifications for the dampers vary depending on factors such as intended application, geographic location and industry standards. Also, it is important to verify that they meet relevant certifications and standards applicable to your specific application. manufacturers should be able to provide documentation showing compliance with the applicable certifications. The following are the certifications and standards applicable to spiral vibration dampers.

- IEC standards – these are standards for electrical equipment including spiral vibration dampers. They provide guidelines for design, testing and performance of various components.

- ISO certifications – this is an internationally recognized quality management standard. It helps to ensure adherence to quality and performance of the product. They provide guidelines for evaluating the performance and effectiveness of the dampers.

- ANSI standards – this is an American standard for certain electrical components including spiral vibration dampers. They may include requirements for vibration damper used in electrical transmission systems.

- National electric code – this is compliance with NESC published by IEEE which is necessary for dampers used in electrical transmission.

- Product certification agencies – product certification agencies such as UL offer certification services for vibration dampers. This is to ensure compliance with applicable safety and performance standards.

- Industry specific certifications – these are specific certifications such as those from organizations such as American wind energy association.

- Customer requirements – some customers may need the spiral vibration damper to meet specific certifications. They may also need them to comply to standards beyond the ones mentioned before.

Frequently asked questions

A spiral vibration damper is a device used to reduce conductor vibrations from winds and other external factors. It consists of a helical coil made of a flexible material to absorb kinetic energy and dampers vibrations.

There are various types of dampers used in overhead transmission and distribution lines. these include helical dampers, yarn dampers, spacer dampers, composite and reformed dampers. Each of these types have different designs based on factors like conductor type, environmental conditions and project requirements.

Spiral vibration dampers need regular inspection, cleaning, tension checks, repair or replacements, assessment of environmental conditions, documentation of maintenance activities and adherence to safety guidelines. Regular maintenance helps to ensure the continued effectiveness and reliability of the dampers.