Biomass is a form of clean energy produced from waste materials, energy crops, agricultural residues, and forest residues. The production method includes cultivation, harvesting, and transportation. South America aims to produce energy from woodchips, given the significant forest resources and agricultural residues. Woodchip-to-energy projects provide a renewable energy source that can diversify the energy mix and reduce reliance on fossil fuels. This contributes to decarbonization efforts by reducing greenhouse gas emissions. Woodchip production and use can create jobs and stimulate economic activity in remote areas. Woodchip is from logging residues, sawmill byproducts, and fast-growing energy crops. They provide carbon neutrality, energy security, and a circular economy. Countries like Brazil, Chile, and Argentina are leading the way in biomass production. Spiral vibration dampers support the facilities for woodchip production to enable power transmission.

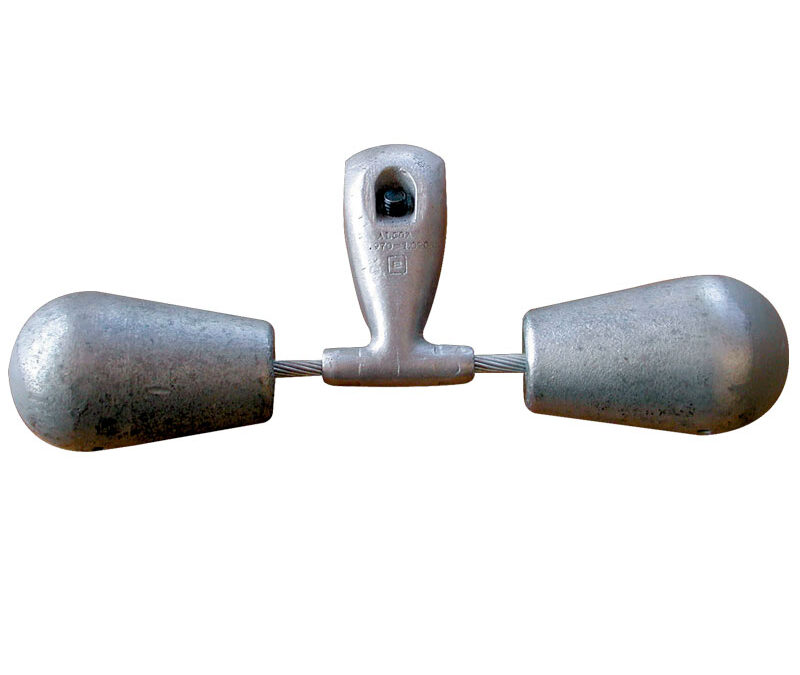

Spiral vibration dampers support power lines to reduce wind-induced vibrations. These vibrations cause stress and fatigue on power line conductors. They absorb and dissipate the vibrational energy to reduce stress on the conductors. Spiral vibration dampers prevent damage to conductors to ensure the reliable transmission of electricity to and from woodchip-to-energy facilities. Additionally, the dampers help to extend the lifespan of power line components. Spiral vibration dampers contribute to the reliability and efficiency of the power grid. This is essential for the successful operation of woodchip-to-energy facilities in South America. This article highlights the opportunities for woodchip production for energy generation. It also looks at the role of spiral vibration dampers in the infrastructure supporting biomass production

The role of spiral vibration dampers in woodchip production

Spiral vibration dampers ensure the efficiency, safety, and longevity of equipment and infrastructure. The dampers mitigate vibrations in power lines, conveyor systems, and industrial equipment. Spiral vibration dampers mitigate the risks related to mechanical and environmental vibrations. The use of spiral vibration dampers improves operational outcomes and supports the long-term growth of biomass. The following are the roles of spiral vibration dampers in woodchip production.

- Protecting conveyor systems—conveyor belts help in transporting raw materials like logs and woodchip across the facility. Vibrations caused by mechanical movement can damage the systems. The dampers reduce vibration amplitudes, which reduces wear and tear on conveyor belts.

- Enhancing power line stability—woodchip production facilities need extensive power infrastructure. The power lines in remote areas are susceptible to vibrations caused by wind. The dampers on power lines reduce oscillations, preventing fatigue and structural failure.

- Improving equipment longevity—high-speed chippers, shredders, and other heavy machinery are prone to vibrations during operations. The dampers mitigate these vibrations to reduce stress on the components.

- Ensuring worker safety—vibrations can lead to instability, noise, and potential safety risks in the production environment. Spiral vibration dampers contribute to a safer working environment. This is by protecting workers from hazards caused by machine instability.

Opportunities for woodchip production for power generation in South America

Woodchip production provides opportunities for South America. This is due to its forestry resources, growing energy demand, and the push for renewable energy adoption. The increased focus on renewable energy makes the region ideal location for woodchip production. Through sustainable practices, investments, and supportive policies, the region can become a global leader in biomass energy. This can drive economic growth and contribute to environmental sustainability. At TTF Power, we are a world-class global provider of high quality overhead line hardware, transmission hardware, distribution hardware, conductors, insulators, cutout switches, anchoring and grounding products. We encourage the development of infrastructure needed to support the woodchip production facilities in the region. Discussed below are the opportunities for woodchip production in power generation.

- Forestry resources—the extensive forests in South America provide raw materials for woodchip production. Countries like Chile, Brazil, Argentina, and Uruguay offer a steady supply of biomass.

- Increasing energy demand—the rise of industrialization, urbanization, and population growth increases energy consumption. Biomass energy provides consistent and reliable electricity to complement intermittent renewables like solar.

- Sustainability – South American countries have set ambitious renewable energy goals. This creates space for biomass in their energy mix. Woodchip biomass is carbon-neutral and can generate carbon credits under global schemes.

- Integration with existing industries—woodchip production can leverage byproducts from forestry. South America’s pulp and paper mills produce wood residues that can be repurposed for energy generation.

- Technological advancements—innovations in woodchip production technology—make the process more efficient and cost-effective. Chipping and processing equipment reduce operational costs and improve quality.