A spool tie connects wires to insulators on poles or towers. It ensures the stability and reliability of the electrical power transmission system. This preformed wire component attaches electrical conductors to spool-type insulators. Its cylindrical shape allows it to wrap around both the conductor and the insulator, simplifying installation and enhancing dependability. Spool ties are from the same material as the conductor, such as aluminum, galvanized steel, or aluminum-clad steel, ensuring compatibility and preventing abrasion. They serve to attach wires, support loads, and maintain electrical insulation. By securely linking conductors, spool ties reduce the risk of them breaking loose.

Important Features of a Spool Tie

Spool ties are available in a range of designs and specifications for attaching electrical wires to insulators. They contain some properties that make them suitable for a wide range of industrial applications. These characteristics provide dependability, lifespan, and cost effectiveness. The spool tie includes the following key elements.

- Material compatibility – spool ties are from the same materials as the conductor. The materials include galvanized steel or aluminum-clad steel. These materials reduce the risk of galvanic corrosion.

- High tensile strength – the spool ties are able to withstand mechanical stresses. This is including tension and compression. They ensure the conductor remains attached to the insulator. They also distribute mechanical loads across the insulators to reduce stress points and reduce risk f failure.

- Electrical conductivity – they also provide a good electrical connection between the conductor and insulator. They help to ensure continuous electrical conductivity for reliability of power transmission.

- Preformed design – the tie manufactures in specific shapes and sizes . This allows them to fit precisely around both the conductor and the spool insulator. This design allows the spool ties to simplify the installation process.

- Secure grip – spool ties are able to grip the conductor, prevent slippage and maintain the position of the conductor on the insulator. They are resistant to environmental factors like wind, ice and temperature changes.

- Cost effectiveness – the durability and reliability of spool ties lead to lower maintenance costs. They also reduce labor costs and time which makes them cost effective.

- Versatility – they are available in different configurations to accommodate various conductor sizes and types of spool insulators. They work in low voltage distribution lines to higher voltage transmission systems.

- Insulation properties – spool ties support the insulation provided by the insulator. This is by keeping the conductor in place. They help maintain the dielectric integrity of the insulator to prevent electrical discharge.

The sections of spool tie

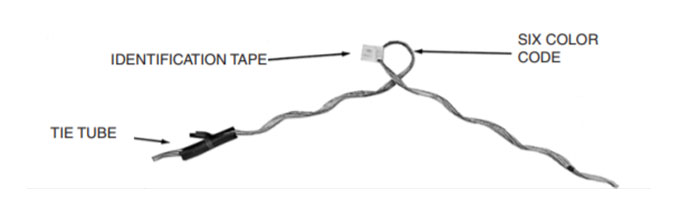

A spool tie’s design and components are specifically developed to provide dependable mechanical and electrical connections. Each spool tie component has a specific job in maintaining the power system’s reliability. These components also ensure that the spool tie connects securely, long-lastingly, and effectively to conductors. The essential components of the spool tie are as outlined below, along with their functions.

- Helical legs – spool ties have helical legs that extend from the preformed wire body. The legs wrap around the conductor to secure the conductor to the insulator. This wrapping technique ensures a tight, slip-resistant fit that withstands environmental forces.

- Gripping sections – the sections of the spool tie that are un contact with the conductor have gripping features such as notches or ridges. These features enhance the tie’s ability to grip the conductor to prevent movement and ensure stable connection.

- Preformed wire body – this is the main component of the spool tie which is from metal wire. It is pre-shaped to fit around the conductor and the spool insulator. Its function is to wrap around the conductor and the insulator to provide a firm grip.

- Material composition – the spool tie materials matches the conductor’s material. This is to ensure compatibility and reduce the risk of corrosion.

- Central groove – this is a groove at the center of the spool tie that fits around the insulator’s neck. This section secures the spool tie to the insulator and ensures proper aligning and positioning.

Specific types of Spool Ties

Spool ties are available in a range of sizes and designs to meet specific requirements and conditions. Their principal function is to connect conductors to spool insulators in overhead transmission lines. The categories differ in their structure, application, and level of security. Additionally, using the appropriate spool ties ensures that the power system is dependable, safe, and efficient. The following are the most common types of spool ties.

- Heavy-duty spool tie – these have a thicker and more robust wire than standard spool ties. These ties include extra gripping features for environments with high mechanical stress.

- Insulated spool tie – these ties use an insulating layer around the wire to prevent electrical conductivity. They serve in applications where electrical insulation between the conductor and the tie is necessary. They prevent electrical faults and ensures safe operation in areas with potential for electrical arcing.

- Standard spool tie – this consists of a preformed wire body with helical legs that wrap around the conductor. It works in standard overhead line applications that experience mechanical stress. They are easy to install and provide secure grip on the conductor.

- Reinforced spool tie – this includes extra reinforcement such as extra wire strands or thicker body. They are ideal for installations that need high mechanical strength.

- Adjustable spool tie – these have adjustable elements that allow for length modifications to fit various insulator sizes. They work in situations that need flexibility in fitting different conductor sizes.

- Preformed spool tie – this is pre-formed to fit specific conductor sizes and insulator type and provide a custom fit. They serve in standard power line installations where consistent performance is crucial. They also provide reliable, secure and tailored fit for specific applications.

Applications of Spool Ties

Spool ties are a versatile component found in transmission and distribution systems. They ensure that electrical connections remain steady and dependable. The spool ties can withstand both environmental and mechanical forces. This makes them essential components. Additionally, they contribute to the stability and efficiency of electrical power networks. Spool ties function in the following applications.

- Rural and urban power systems – spool ties are essential in maintaining the stability and long-span lines. They help to manage the complexity of power lines running through congested areas.

- Distribution and transmission lines – spool ties work in low, medium and high voltage transmission lines. They work where conductors need fastening to insulators. This is to maintain proper clearance and tension.

- Temporary and emergency installations – spool ties serve in temporary installations where quick and secure conductors attachment is necessary.

- Renewable energy projects – spool ties serve to secure conductors to insulators in areas exposed to high winds. they also help manage and secure conductors in exposed and elevated positions.

- Severe weather and high wind areas – spool ties provide reliable conductor attachment. This helps to prevent dislodging or damage of the conductors. They work in areas with high wind loads where maintaining conductor stability is critical.

- Grid maintenance and upgrades – spool ties aid in routine maintenance and upgrades. They help to resecure conductor attachments or repair.

- Vibration and Aeolian vibration control – the ties can have features that help dampen vibrations. The spool ties help manage Aeolian vibrations which can cause conductor fatigue and damage.

- Utility pole infrastructure – spool ties serve in utility pole infrastructure to secure conductors in vertical and horizontal configurations. They also serve where many conductors attach to insulators mounted on Crossarms.

Advantages of using spool ties in overhead transmission lines

The usage of spool ties in overhead transmission lines has some advantages that improve reliability and safety. They are versatile and resilient, making them essential to the stability of power systems. The following are the benefits of using spool ties.

- Simplified installation – preformed spool ties have designs for easy installation and reduces the need for specialized tools.

- Enhanced mechanical strength – the ties distribute mechanical stress across the conductor and insulator to reduce wear and tear. They have design to withstand mechanical forces such as tension and compression.

- Improved electrical performance – spool ties help ensure continuous electrical conductivity by maintaining a secure attachment.

- Secure and reliable conductor attachment – spool ties provide a secure connection between the conductor and the insulator. This attachment reduces the risk of conductor slipping or becoming loose which can lead to power outages.

- Corrosion resistance – spool ties are from the same material as the conductor to prevent galvanic corrosion. They also have coatings that protect them from environmental factors like moisture, salt and pollutants.

Frequently asked questions

A spool tie helps to secure electrical conductors to spool insulators on utility poles or transmission towers. It secures the conductor to prevent movement and maintain the reliable electrical connections.

Spool ties are more prevalent in low and medium voltage lines, although they can also serve in high-voltage applications.

Spool ties assist in keeping conductors secure and stable, preventing inadvertent disconnections and electrical failures. Insulated spool ties also improve safety by preventing electrical contact and arcing.