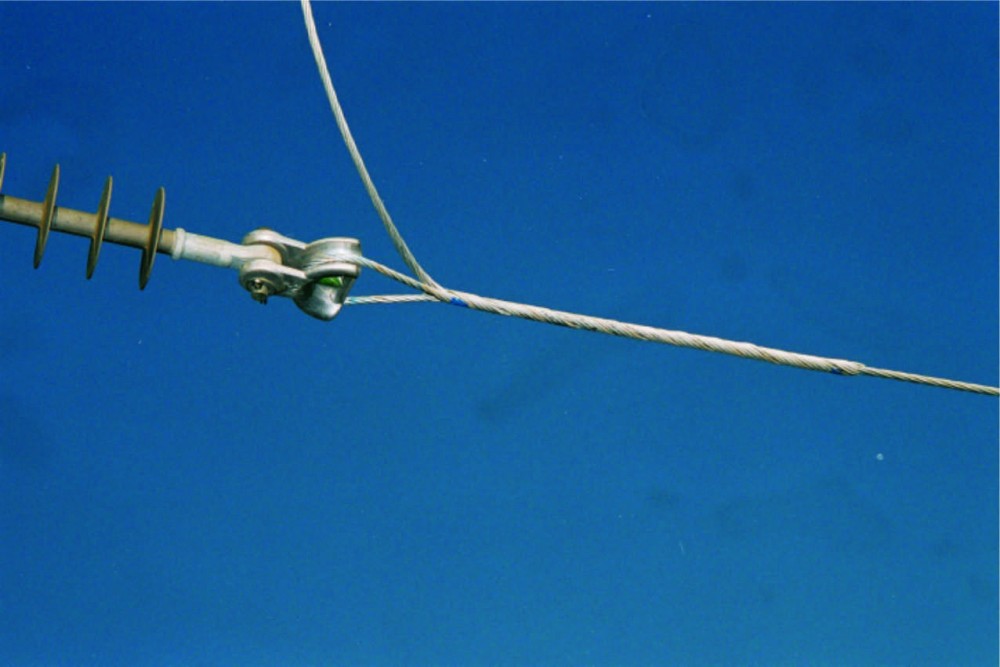

A thimble clevis is a device used to attach conductors to insulators and other support structures. It helps to ensure the reliable and safe transmission of electricity in various applications. Thimble clevis consists of a thimble-shaped metal component with a loop, groove or hole at one end. This part is crucial to accommodate the conductor. The other end has designs for attachment to the insulator using a pin, bolt or other fasteners. Thimble clevises help to maintain the proper alignment and tension of conductors. This prevents the conductors from sagging or becoming loose. This in turn reduces the risk of power outages or safety hazards. They are from materials that are able to withstand mechanical loads and environmental conditions. Clevises find use in applications like transmission and distribution lines.

Types of thimble clevis

Thimble clevises come in a variety of designs and serve a purpose in overhead transmission lines for particular purposes. Consider the size of the conductor, mechanical load, the environment and project requirements. The many thimble clevis types used on the transmission lines are as covered here.

- Heavy-duty thimble clevis – these have designs to withstand higher mechanical loads and offer increased strength and durability. They work in areas where the conductor faces significant tension.

- dead-end thimble clevis – these work in dead-end configurations where the conductor terminates at a support structure. They have designs o anchor the conductor and distribute mechanical loads.

- Standard thimble clevis – this is the most basic and most used type of thimble clevis. It consists of a U-shaped clevis and a cylindrical thimble that fits inside. They work in general purpose applications and provide reliable support for conductors.

- Angle thimble clevis – these clevises find use in applications where the conductor needs to attach at an angle. They have an angular design to accommodate installations while maintaining a secure connection.

- Insulated thimble clevis – these clevises have an insulating material like polymer or composite integrated into the thimble. They provide electrical insulation cut the risk of electrical leakage.

- Adjustable thimble clevis – these clevises have an extra feature that allows for adjusting the tension. They have a threaded part or mechanism for fine tuning the position of the thimble within the clevis.

- Ball and socket – ball and socket feature a ball joint connection between the clevis and the thimble. This connection allows for some angular movement and flexibility. This allows for slight misalignment between the conductor and the supporting hardware.

Classification of thimble clevises

Thimble clevises classify according to factors such as design, size, load capacity and intended application. This helps to ease the selection of the most suitable type for your specific installation requirements. The following is the classification of thimble clevises.

- By design – according to design, there are various types such as standard clevis, adjustable clevis and ball clevis. These types accommodate the conductor, allow change and swiveling movement.

- By size – the clevises are available in various sizes to accommodate different conductor diameters and types. They may also classify according to the diameter and size of the conductor.

- By load capacity – the clevises have ratings showing the greatest mechanical load they can withstand. They may be light-duty, medium-duty or heavy-duty thimble clevises.

- By application – they may find use in transmission, distribution lines and substation equipment. They may classify according to their voltage levels, conductor types or environmental conditions.

- By material – the thimble clevises may classify based on the material of construction. These materials include steel, aluminum or other corrosion resistant materials.

- By specialty – there are specific clevises used in dead-end configurations and angle applications. these may need the use of dead-end clevises or angle clevises.

Application areas of thimble clevis

A crucial element in the building, running and upkeep of transmission lines is the thimble clevis. With its application, the conductors are securely supported, ensuring the safe and dependable transmission of electric power. Additionally, it maintains the appropriate degrees of tension and distributes loads. The following uses for thimble clevis appear in overhead transmission lines.

- Distribution lines – the clevises work in distribution lines to help deliver electricity from transmission lines to homes and businesses. They play a crucial role in ensuring the stability and reliability of distribution systems.

- Transmission lines – thimble clevises attach the conductor to the other hardware components in the systems. They provide reliable and sound connection ensuring the conductor remains in place.

- Telecommunication lines – the clevises support electrical cables and wiring in telecommunication lines. they help maintain the integrity of electrical connections and prevent cable sagging.

- Adjustability – thimble clevis allows for easy tension change during installation or maintenance of the transmission line.

- Conductor suspension – the devices suspend or support the conductors in overhead transmission lines. They also provide a secure connection between the conductor and the supporting structure like poles and towers.

- Insulation and protection – thimble clevises distribute the mechanical loads and stresses along the length of the conductor. They act as a barrier between the conductor and the metal clevis reducing the risk of abrasion, wear and damage to the conductor’s insulation.

- Renewable energy systems – the clevises support electrical cables and wiring used in wind farms and solar power plants. They play a crucial role in ensuring the efficient and reliable operation of renewable energy infrastructure.

- Load distribution – they distribute the mechanical loads and stresses along the length of the conductor. They also distribute the weight and tension on the lines to prevent stress concentration points.

Materials used in the construction of thimble clevises

Thimble clevises are from high-strength materials that provide durability, corrosion resistance and mechanical stability. The material selected depends on factors such as the application environment, load requirements and desired longevity. Additionally, each material offers specific advantages and suitability for different applications and environments. The following are the common materials used for thimble clevises.

- Steel – this is a popular choice for thimble clevises due to its excellent strength, durability and resistance to mechanical stresses. Steel clevises work in medium to heavy applications and other outdoor applications.

- Aluminum – clevises from aluminum are lightweight and offer good corrosion resistance. This makes them ideal for applications exposed corrosion elements. They work in overhead transmission and distribution lines.

- Stainless steel – stainless steel provides excellent corrosion resistance in aggressive environments. These are environments with exposure to chemicals. They work in applications in coastal areas or chemical processing facilities.

- Composite materials – these include fiberglass-reinforced plastic or polymer composites. The materials offer advantages such as lightweight, corrosion resistance and electrical insulation properties.

- Galvanized steel – the clevises have a layer of zinc to provide corrosion resistance. They are suitable for outdoor applications. These are applications prone to exposure to moisture, humidity and atmospheric corrosion.

- Copper – the clevises from copper offer excellent electrical conductivity and corrosion resistance. This makes them suitable for applications where electrical conductivity is critical.

- Bronze – these clevises offer good corrosion resistance and work in marine and underwater applications. This is where they are prone to seawater and harsh environmental conditions.

Functions of thimble clevises

Thimble clevises serve important functions in electrical installations in transmission and distribution lines. they provide secure attachment, alignment, load distribution and electrical continuity. This also helps to ease installation and maintenance processes and enhancing safety. The following are the key functions of thimble clevises.

- Secure conductor attachment – the clevises provide a secure attachment point for conductors to insulators. They ensure the conductor remains in place to prevent it from becoming loose.

- Distribute mechanical loads – thimble clevises distribute mechanical loads along the length of the conductor. This helps reduce stress concentrations and reduce the risk off mechanical failure. They also help to distribute the weight of the conductor and any extra loads to ensure structural integrity.

- Ensure electrical continuity – the clevises help maintain electrical continuity in transmission and distribution lines. They also ensure the electrical current can flow through the conductor without interruptions.

- Enhance safety – the clevises ensure the safety of overhead electrical systems by anchoring conductors. They also contribute to the reliability and safety of the electrical installation.

- Maintain conductor alignment – the clevises help maintain the proper alignment of conductors in overhead transmission lines. they also ensure the conductor is well positioned and tensioned to reduce sagging.

- Ease installation and maintenance – the clevises have designs for ease of installation and maintenance. This is also to allow for quick and straightforward attachment of conductors.

Frequently asked questions

A thimble clevis is a hardware component used in electrical installations to attach conductors to insulators. It ensures proper alignment, load distribution and electrical continuity in the system.

Thimble clevises are from materials such as steel, aluminum, stainless steel and composite materials. The choice of the material depends on factors such as load requirements, environmental conditions and desired performance characteristics.

Consider factors such as the application environment, load requirements, conductor size, compatibility with insulators or support structures.