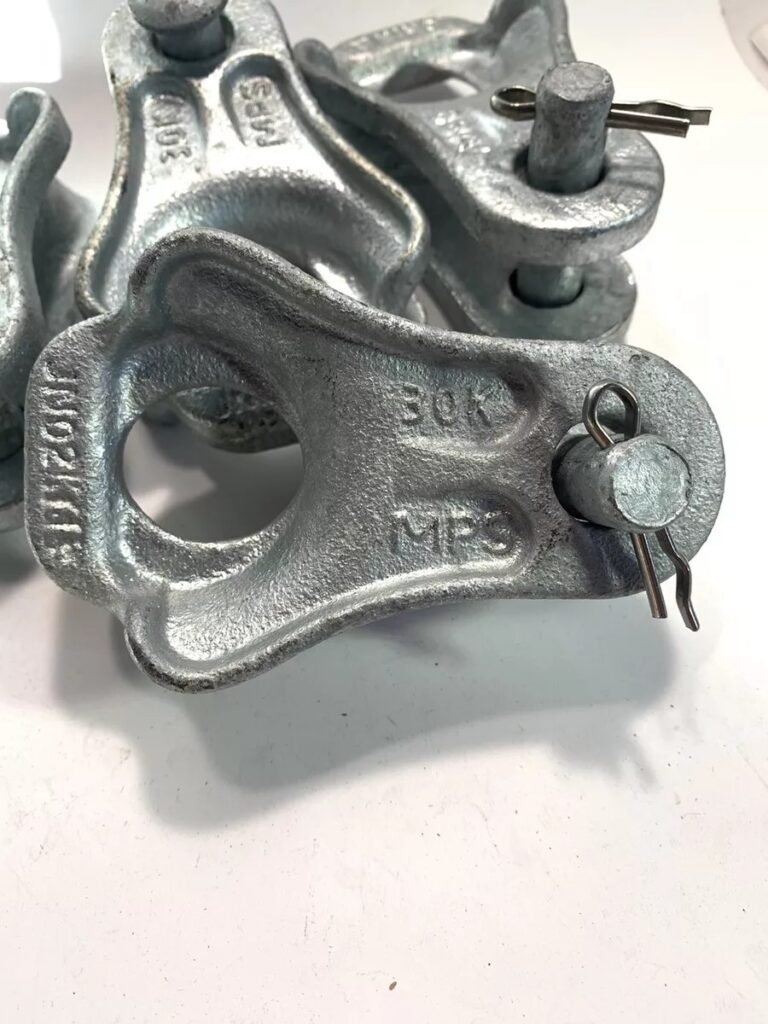

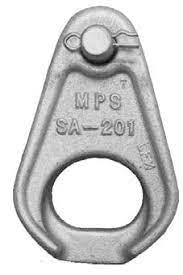

A thimble clevis is a device used to create and maintain overhead electricity lines. It is useful to connect the conductor to an insulator. A thimble clevis resembles a thimble, with a closed loop at one end and a clevis pin hole at the other. The clevis attaches to the insulator via the closed loop, and the clevis pin hole binds it to the support structure. Thimble clevises are from materials like galvanized steel or aluminum alloy. These materials add longevity and strength to the application. Clevises help to provide mechanical support and stability to the system. They also help attach insulators to crossarms, ensuring adequate conductor suspension. Thimble clevises have designs to withstand mechanical loads.

Factors to Consider When Choosing Materials for Thimble Clevis

Thimble clevises are from a variety of materials, which add to their durability and functionality. Steel, aluminum and composite materials are often used materials. It is advisable to choose materials that fulfill the specific needs of their applications. The goal is to improve their performance, durability, and cost-effectiveness. The following are some variables to consider while choosing materials for thimble clevises.

- Strength and load capacity – the materials used should be strong enough to sustain mechanical loads and stress. The material should have the maximum load capacity specified for the planned uses.

- Durability and lifespan – the materials should be durable enough to resist the rigors of outdoor use. Choose a material known for its durability to reduce maintenance requirements and lengthen service life.

- Cost -this should include both the initial purchase price and long-term maintenance and replacement costs. High-performance materials are more expensive but provide better durability and cost-effectiveness.

- Environmental impact – assess the material’s environmental impact across its whole existence. This includes raw material extraction, production processes and disposal. This also contributes to compliance with sustainability goals and legal standards.

- Corrosion resistance – thimble clevises must withstand adverse environmental conditions such as dampness, salt and chemicals. Choose a material with a strong corrosion resistance to ensure dependability and durability.

- Weight – the weight of the material influences the weight and handling properties of thimble clevises. To ensure performance and usability, strike a balance between strength and weight.

- Manufacturability – this refers to the material’s suitability for the manufacturing methods used. Compatibility guarantees efficient production and consistent quality in completed products.

- Compliance – the clevises should adhere to appropriate industry norms and requirements. These are requirements for material composition, mechanical properties and performance.

Supplier and dealer details for thimble clevises

There are several suppliers and vendors of thimble clevises on the market. Selecting the best supplier might be a difficult undertaking. There are several aspects to consider to ensure dependability, quality and compatibility. Furthermore, it is advisable to choose a reputable supplier who can meet the quality, delivery and service criteria. The following are common variables to consider when choosing a supplier or vendor.

- Reputation – consider the supplier’s experience and reputation in the industry. They should have a track record of delivering thimble clevises to respected businesses and finishing projects.

- Lead time and delivery – determine the supplier’s lead time for processing orders and delivering the clevises to your site. This helps to achieve schedules and cut downtime during power line installation activities.

- Customer Support and Services – check the supplier’s levels of customer help and service. This includes attention to requests, technical help and post-sales support.

- Sustainability – consider the supplier’s commitment to sustainability and environmental responsibility. Choose suppliers who focus on manufacturing techniques, waste reduction initiatives and ethical sourcing.

- Product quality – inspect the thimble clevises from the supplier. This includes materials used, production procedures and compliance with industry standards.

- Certifications – ensure that the thimble clevises meet applicable industry standards and regulations. Check for certifications like ANSI and IEC to ensure product quality and safety.

- Customization possibilities – determine whether the supplier offers customization choices to fit your individual needs. This includes variances in size, load capacity, finish and other characteristics.

- Cost effectiveness -compare prices from several suppliers to ensure competitive rates. Consider volume discounts, bulk purchase alternatives and the cost of ownership.

- Supply chain – check the supplier’s supply chain reliability, including their capacity to get raw materials. Ensure that the supplier has adequate plans to mitigate potential disruptions.

Advantages of Using Thimble Clevises in Your Application

Thimble clevises play several roles in overhead transmission and distribution power networks. They provide various benefits that assure the application’s continuing performance. Using thimble clevises helps to maintain structural integrity, dependability and safety. Furthermore, it is critical to comprehend the advantages that the chosen thimble clevis provides. The following are the advantages of utilizing thimble clevis in overhead transmission lines.

- Mechanical stability – the clevises ensure a secure and sturdy connection between the insulators and support structures. This helps to ensure that the conductors are properly suspended and insulated, preventing drooping and sway.

- Versatility – the clevises are suitable with a wide range of insulators, crossarms, and support structures. This makes them appropriate for a variety of power line arrangements.

- Simple installation – this is simple because the clevises are for this purpose. It enables the quick and effective assembly of power line components.

- Reduced maintenance – the clevises help reduce the need for maintenance and repairs, which improves system reliability.

- Load distribution – the clevises aid in the distribution of mechanical loads throughout the power line system. This lowers stress concentrations and the likelihood of structural failure.

- Corrosion resistance – thimble clevises are from corrosion-resistant materials. These materials include galvanized steel or aluminum alloy. The materials offer long-term durability and dependability in outdoor settings.

- Cost effectiveness – clevises provide a low-cost solution for attaching insulators to support structures. This provides dependable mechanical support at a lower cost than other approaches.

Common test for thimble clevises

Thimble clevises go through many tests to assure their quality, dependability and safety. They also guarantee that they meet performance and regulatory standards. Additionally, it is critical to speak with professionals for advice on the appropriate testing. The following are the many testing methods the thimble clevis undergoes.

- Dimensional inspection – this confirms that the thimble clevis meets the stipulated dimensional criteria. This includes the length, width, diameter of the closed loop, and the diameter of the clevis pin hole.

- Corrosion resistance testing – this tests the clevis’s corrosion resistance by subjecting it to accelerated corrosion tests. This involves salt-pray testing to simulate extreme environmental conditions.

- Fatigue testing – this involves subjecting the clevis to many loading cycles to determine its resistance to fatigue failure.

- Environmental testing – this entails exposing the clevis to environmental conditions relevant to its intended application. This includes harsh temperatures, dampness and UV radiation. This evaluates its performance and durability in real-world environments.

- Load testing – this entails subjecting the clevis to mechanical load tests to determine its strength and load bearing capacity. This entails applying a static load on the clevis and determining its deformation.

- Material analysis – this involves performing tests such as chemical composition analysis and mechanical property testing. This is to ensure that the material used in the clevis satisfies particular norms and specifications.

- Fit testing – involves determining the compatibility and fit of the clevis with other components of the power line system.

Price comparison for thimble clevis

Thimble clevises sell based on a variety of factors. Material, size, load capacity, quantity, and supplier pricing are all important considerations. Considering these considerations allows you to make an informed decision about the best cost-effective clevis for your application. Prices for small thimble clevis range from $5 to $15, medium from $15 to $30, and large from $50 to $100. The following are the methods for doing cost comparisons.

- Material – the clevises are from various materials, which affects their cost. This is due to variances in material costs and manufacturing procedures.

- Quantity – it is critical to assess the entire quantity required for your project and purchase in bulk for discounts.

- Extra services – some providers provide extra services such as customization, technical support and shipment. When comparing quotes, take into account the worth of these services.

- Total cost of ownership – consider the total cost of ownership for the clevises during their entire lives. This includes the initial cost of purchase, maintenance and replacement expenditures.

- Size and load capacity – clevises are available in a variety of sizes and load capacities to suit different power line designs.

- Quality and reliability – focus on quality and reliability when selecting thimble clevises.

Frequently asked questions

In overhead power line construction, a thimble clevis connects insulators to support structures. Its function is to give mechanical support and stability for the power line system.

Thimble clevis cost comparisons take into account material, size, load capacity, quantity, and supplier/vendor pricing. Requesting quotations from different providers and calculating the total cost of ownership over the lifecycle of the clevises can help you make an informed choice.