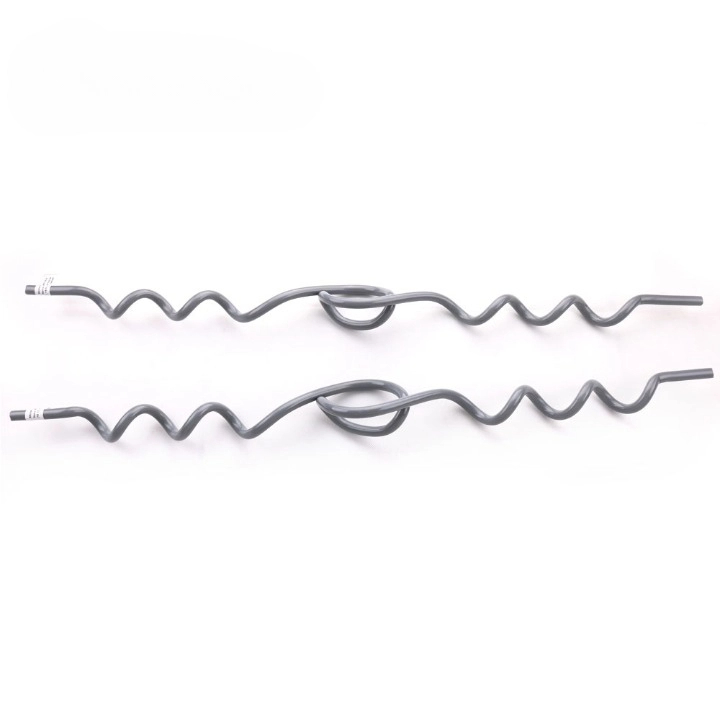

A top tie is a piece of hardware meant to secure and support conductors in overhead transmission cables. It is also used to secure ADSS and OPGW cables that support structures such as utility poles and towers. A top tie for ADSS/OPGW cables serves to keep the cable in place while reducing stress and potential damage to it. These top ties are helical in design, allowing them to wrap around the cable and support structure. The ties must be capable of supporting both the mechanical load and the electrical grounding requirements. Top ties provide a stable connection that can resist a variety of environmental conditions. They consist of high-strength, robust materials that provide long-term performance.

Materials required to make a top tie for ADSS/OPGW cables

Top ties for ADSS/OPGW cables originate from materials chosen for mechanical strength, longevity, and compatibility. Material selection depends on the specific requirements of the environment. The right top tie selection ensures ADSS and OPGW cables’ dependability and long-term support. The following are materials used in the manufacture of top ties.

- Galvanized steel – this is steel coated with a layer of zinc to prevent corrosion. They work in environments where high mechanical strength is necessary.

- Aluminum alloy – this is lightweight, corrosion resistant and robust. It is suitable for ADSS cables in areas with high corrosion potential.

- Aluminum clad steel – this combines the strength of steel with the corrosion resistance of aluminum. It provides a strong and durable solution that can withstand harsh environmental conditions.

- Stainless steel – this is resistant to corrosion and provides excellent mechanical strength. It works in areas with high exposure to corrosive elements.

- Fiberglass reinforced polymer – this is a non-conductive, lightweight and corrosion resistant material. The top tie is ideal for ADSS/OPGW cables in high voltage environments. They help to reduce electrical conductivity of the support structure.

- Thermoplastic materials – this is a non-conductive material that is resistant to UV radiation and weathering. It also provides a non-metallic option that is easy to handle and install.

Conductors appropriate for a top tie

Top ties exist to secure various types of conductors that support structures in overhead transmission lines. Conductors used with top ties in ADSS/OPGW cables have distinct properties. This ensures that the application system is both compatible and effective. The conductors used with top ties are as listed below, along with their features.

- Aluminum conductor steel reinforced (ACSR) – these conductors feature a steel core for strength and aluminum strands for conductivity. The steel core provides mechanical strength for long spans between structures.

- OPGW cables – these cables combine optical fibers for communication with metallic conductors for grounding and protection. The metallic components ease grounding and protect the cable and the infrastructure.

- Aluminum conductor alloy reinforced (ACAR) – these conductors consist of aluminum alloy strands. They provide a balance between strength and conductivity. They are easier to handle and install with a top tie compared to ACSR.

- ADSS cables – these are non-metallic components that make them immune to electromagnetic interference. They are able to withstand various environmental conditions. This is including UV radiation, temperature changes and precipitation.

- Aluminum alloy conductors (AAC) – this conductor is from aluminum alloy which provides uniform properties. They provide excellent electrical conductivity with good mechanical strength.

Best ties for ADSS and OPGW wires

Top ties connect ADSS and OPGW cables to their support structures in telecommunications networks. The top ties must have precise features to give adequate support. This occurs while ensuring the cables’ integrity and functionality. Additionally, top ties must be suitable with cable diameter, give a solid grip, and be easy to maintain. The following are the characteristics of top ties for ADSS/OPGW cables.

- Helical design – this is the spiral shape that wraps around the cable. This helps to distribute pressure along the length of the cable to reduce the risk of localized stress.

- UV and weather resistance – the top tie should be resistant to UV radiation, moisture, temperatures and other factors. This is to ensure durability and reliability for ADSS cables in outdoor installations.

- Non-conductive material – the top ties should be from dielectric materials to prevent electrical interference. It should also ensure compatibility with the all-dielectric nature of ADSS cables.

- High tensile strength – the ties should be able to withstand the mechanical loads from the cable and environmental factors. This helps to provide secure support and reduce sagging over long spans.

- Corrosion resistant materials – top ties for OPGW cables should be from corrosion resistant materials to ensure durability.

- Ease of installation – the top tie should have designs that allow quick installation without need for special tools. This is to reduce labor costs and installation time to ensure a secure fit.

- Mechanical strength – the ties should have high tensile strength to handle the combined weight of the cable and other loads. This helps to provide a strong support for the cable and prevent excessive sag.

- Electrical conductivity – the top ties for OPGW cables should be suitable for grounding and bonding with the metallic components of the cable. This is to ensure proper grounding and enhance safety and performance.

Cost analysis and considerations for top ties

There are various styles, designs, and providers of top ties on the market, with varying price ranges. Several factors determine the price of top ties. Also, it is important to weigh the initial expenditures of top ties against their long-term benefits and performance. Request bids from various providers to compare rates before selecting the best ties. The following factors determine the cost of top ties.

- Design and engineering – top ties with helical or spiral designs may cost more than standard designs. This is due to the precision required during manufacture. Custom-designed top ties for specific cable diameters cost more compared to standard designs.

- Installation costs – top ties with quick installation designs reduce labor costs with no need for special tools.

- Environmental conditions – investing in corrosion-resistant materials like stainless steel can be cost-effective. Top ties exposed to extreme weather conditions need to be from materials and designs that can withstand the stresses.

- Material costs – there are different materials used in the construction of top ties. Check their performance, durability and costs. Aluminum-clad steel is more expensive due to its strength and corrosion resistance. High-quality materials last longer and perform better under harsh conditions.

- Volume and bulk purchasing – purchasing top ties in bulk can reduce the costs per unit and potential discounts for large orders.

- Total cost of ownership – consider the upfront costs, installation costs, maintenance, replacements and any other operational disruptions.

- Supplier and brand – established brands and reputable suppliers might charge a premium for their products. Extended warranties and robust customer support might have higher upfront costs. They may offer savings through reduced maintenance expenses.

- Regulatory and compliance costs – ensuring that top tie meet standards and certifications influences their costs. Compliant products have higher manufacturing standards and related costs.

Supplier details for top ties

There are various providers and manufacturers of top ties on the market to choose from. The appropriate choice guarantees the highest quality, dependability, and value for top ties. Further, it is critical to choose a supplier who satisfies both your current needs and the long-term success of your cable installations. The following are the factors to consider when picking a top tie supplier.

- Supplier reputation – consider suppliers with a proven track record and extensive experience in manufacturing a top tie. Check for references from other customers and read reviews to gauge their reputation.

- Technical support and service – check the level of technical support provided by the supplier. This is including help with product selection, installation guidance and troubleshooting.

- Quality and compliance – verify that the supplier uses high-quality materials suitable for the intended application. Check for suppliers who conduct rigorous testing and quality control processes.

- Customization and flexibility – assess the suppliers range of products for top ties that meet your specific needs. Select suppliers that can handle both small and large orders. They should also offer flexibility in schedules and order adjustments.

- Cost and value – compare pricing from various suppliers to ensure competitive rates. Consider the long term costs including installation, maintenance and potential replacements.

- Innovation and technology – check for suppliers who invest in research and development to provide innovative solutions. Consider the suppliers who use advanced manufacturing technologies to ensure high quality products.

- Logistics and delivery – check the suppliers lead times and their ability to meet project’s timelines. Consider the geographical reach and delivery network.

- Financial stability – assess the financial stability of the supplier to ensure they continue to support your needs.

Frequently asked questions

Top ties are hardware components used to secure ADSS and OPGW cables to support structures. Their main function is to hold the cables in place and reduce stress and potential damage.

Supplier financial stability ensures consistent supply, long-term support, and reduced risk.

The helical design of a top tie distributes pressure evenly, provide secure attachment and reduces installation stress.