Did you know a crossover clamp can help avoid a destructuve phenomenon called galloping conductors? The clamps are silent guardians of the electricity frlow in overhead transmission lines. Crossover clamps prevent the galloping through maintaining proper spacing and increasing stability. They are from high strength materials that make the conductors less susceptible to wind oscillations. The clamps install at the points where the conductors intersect on the transmission lines. Crossover clamps are from materials such as aluminum, galvanized steel and composite polymers. These materials provide conductivity and corrosion resistance. Common types onclude hydraulic crossover clamps which handle high tension. Use of crosover clamps on your application helps to ensure a steady flow of electricity even during high wind scenarios.

Different types of crossover clamps for your transmission lines

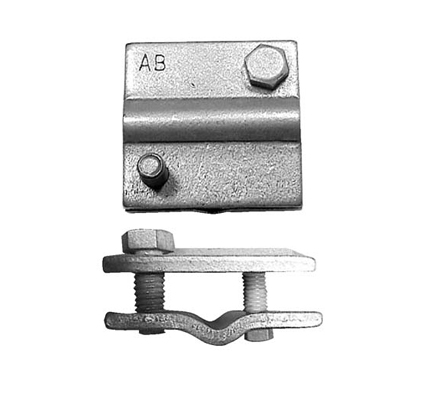

Use of crossover clamps on overhead transmission lines prevent sparks, outages and fires. They are available in different designs tailored to specific needs and environments. Each crossover clamp has its individual benefits and limitations. The following are the common types of crossover clamps.

- Tension clamps – these clamps wok on high-voltage transmission lines carrying immense electrical currents. They have strong designs built to withstand immense pulling forces. The clamps also have grooves to grip the conductors in a tight position. This prevents slippage and ensures uninterrupted power flow.

- Angle clamps – the clamps work at the positions where two power lines cross each other at an angle. They have a V-shaped design that accommodates the line intersection. They work for low-voltage lines and offer easy installation and maintenance.

- Hydraulic crossover clamps – these clamps use hydraulic pressure to apply a powerful grip on conductors. This makes them ideal for high tension applications and challenging environments.

- Dead-end clamps – the clamps anchor the conductors to towers or structures which prevents them from sagging. They help to maintain the line stability and safety.

- Parallel clamps – these are suitable for situations where two lines run parallel to each other before crossing. They are straight, sturdy design which ensures perfect alignment and spacing. They find use in applications such as high voltage applications.

- Cable clamps – these are smaller clamps that help secure and insulate smaller diameter cables. They work in telecommunications or distribution lines.

Common materials and properties of crossover clamp

Crossover clamps are from materials that offer strength, conductivity and corrosion resistance. This helps to ensure reliable performance in various environments. Properties of crossover clamps vary depending on the material used. The selection of materials vary depending on factors like voltage level, conductor type and size, environmental and weather conditions and specific application requirements. The following are the materials and properties for crossover clamps.

- Stainless steel – crossover clamps from stainless steel are corrosion resistant . This makes them suitable for harsh environments. They also offer durability and longevity despite their high costs.

- Galvanized steel – galvanization process involves coating the steel with a layer of zinc. This coating provides corrosion protection which is essential for outdoor applications.

- Aluminum – crossover clamps made from aluminum are lightweight and offer good conductivity. This makes them suitable for electrical applications like transmission lines. they are also corrosion resistant which helps in outdoor applications.

- Composite polymers – this material provides a lightweight alternative to metal clamps. They also provide good resistance to corrosion. They also resist chemicals, UV radiation and are electrically non-conductive.

- Conductivity – crossover clamps should have good conductivity. This helps to allow for the flow of electrical currents without resistance.

- Durability – the clamps should be durable enough to withstand long-term exposure to environmental conditions, mechanical stresses and operational requirements.

- Adjustability – some clamps have adjustable features to accommodate different conductor sizes. This provides flexibility in installation and maintenance.

- Corrosion resistance – the clamps should be corrosion resistant to maintain their structural integrity. This is because they install in outdoor environments exposed to moisture, chemicals and other elements.

- Insulation – insulating properties prevent contact between conductors and the clamp itself. Materials like composite polymers and ceramic inserts provide high-temperature resistance. They also offer electrical insulation for special applications.

- Temperature resistance – the clamps should withstand a wide range of temperatures without compromising performance.

- Strength – crossover clamps should withstand mechanical stresses and loads. These loads include tension and compression.

What are the technical specifications to consider for crossover clamps

Selecting the right crossover clamp for transmission lines requires considerations of the specifications. The right technical specifications ensure safe and reliable operations of your applications. The technical details of the clamp can vary depending on the type of crossover clamp. Additionally, it is advisable to consult with manufacturers specifications and seek advice from qualified professionals. The following are the technical specifications to consider for crossover clamps.

- Size and compatibility – govern the size of the conductors the clamps will work with. Ensure they are compatible with the diameter, shape and type of the conductors.

- Load capacity – determine the mechanical stress the crossover clamps can withstand without fail. Consider factors such as tension, compression and bending moments that may affect the load capacity.

- Locking mechanisms – check the design and effectiveness of the locking mechanisms used in the clamps. Consider factors such as ease of installation, security of the connection and resistance to vibration.

- Temperature range – analyse the operating temperature in which the crossover clamps will use. Ensure the clamps can withstand temperature variations without compromise.

- Installation requirements – consider any specific installation requirements. This is including space limitations, mounting configurations of accessibility. Ensure the clamps are compatible with the selected tools and method of installation.

- Environmental conditions – consider the environmental factors such as exposure to moisture, chemicals, UV radiation and atmospheric conditions

- Corrosion resistance – assess the corrosion resistance of the clamps. Consider the material composition and surface treatment.

- Voltage rating – ensure the clamps have ratings for the voltage level of the electrical system intended for use.

- Material – consider the material composition of the clamps and check the properties of the material. This is including strength, conductivity, corrosion resistance and durability.

Industry advancements and updates for crossover clamps in the market

The market for clamps continues to advance in ways that contribute to their functionality and efficiency. The advancements highlight the dynamic nature of the crossover clamp industry. The development of more innovative solutions enhance the reliability, safety and sustainability. Staying informed about these advancements help you make an informed decision during decision-making. Additionally, it is advisable to consult with industry experts for guidance on the best advancements. The following are the various industry advancements and updates for crossover clamps.

- Digitalization – this could lead to crossover clamps equipped with Internet of Things capabilities. This is for remote monitoring and control. This could enable utilities to optimize operations, improve reliability and respond to maintenance needs.

- Smart technologies – integration of smart technologies could enable real-time monitoring. This is for factors such as temperature, load and vibration. These technologies include sensors and monitoring systems. The collected data could help in predictive maintenance and proactive management of transmission line assets.

- Material innovation – manufacturers provide new materials such as composite materials with enhanced properties. These properties incluse increased strength, conductivity and corrosion resistance. They offer improved performance and durability for crossover clamps in harsh environments.

- Design optimization – there could be advancements in the design of crossover clamps to optimize functionality and ease of installation. This includes features such as adaptable locking mechanisms, modular designs for compatibility with different conductor sizes.

- Environmental sustainability – this includes use of eco-friendly materials and manufacturing processes. It includes recyclable materials, energy efficient production methods and reduced environmental impact.

Community forums and engagement for crossover clamp

Engaging with community forums and online platforms provides updated clamp advancements and knowledge sharing. It also helps to connect with industry professionals for more insights. The following are the forums and platforms to engage with crossover clamp community.

- Webinars and virtual events – these are events that cover topics related to electrical engineering. They may include sessions on crossover clamps and other overhead components.

- Industry associations and forums – this includes platforms like Reddit and Quora host communities. Professionals discuss various topics related to electrical engineering and crossover clamps.

- LinkedIn groups – these are groups related to electrical engineering, power transmission or utility infrastructure. This helps to connect with professionals who work with crossover clamps.

- Manufacturer websites and forums – some manufacturers have online forums. They allow clients to ask questions, share feedback and discuss product related topics.

Frequently asked questions

Crossover clamps work in electrical and utility infrastructure to connect and support conductors at crossover points. They help to ensure proper alignment, continuity and electrical safety.

The technical specifications to consider include size and compatibility, material composition, load capacity, voltage rating, locking mechanism, corrosion resistance and environmental conditions.

There are various challenges such as balancing costs and innovation, adapting to new technologies and meeting evolving regulations.