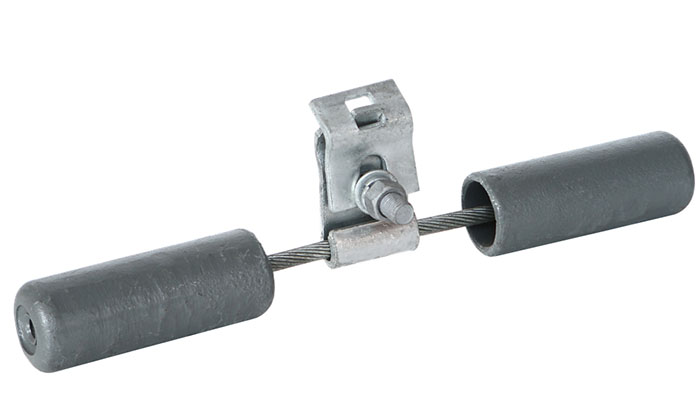

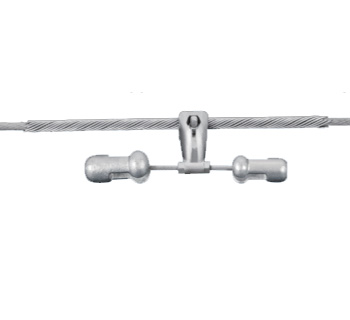

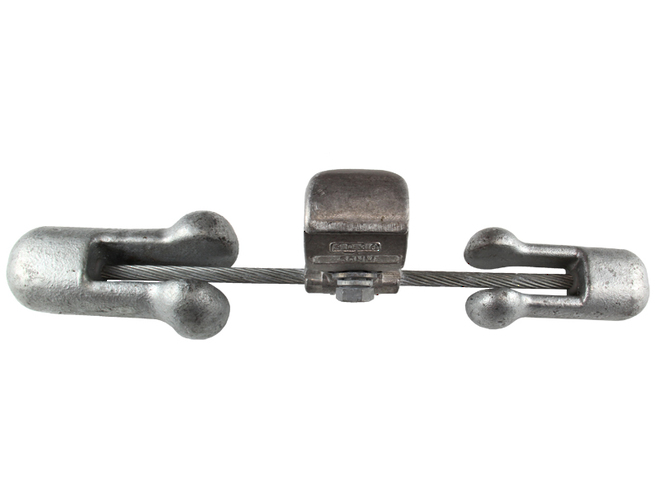

A spiral vibration damper is a device used to reduce aeolian vibration from strong winds on transmission lines. The dampers are also known as Stockbridge dampers. The dampers instal at intervals along the length of the line. It consists of a spiral-shaped metal structure that wraps around the conductor. This shape helps to dissipate the energy of the wind-induced vibrations and reduces stress on the conductor. Spiral vibration dampers work on transmission lines to improve the lines resilience. Various environmental factors can lead to wear and tear on the lines and support structures. Spiral vibration dampers find use in applications to reduce damage risks.

Functions of spiral vibration dampers

Spiral vibration dampers have various functions to overhead transmission lines. the main function is to reduce vibrations, prevent galloping and enhance system reliability. The following are the functions of spiral vibration dampers in overhead transmission lines.

- Reduce vibrations – dampers reduces the amplitude of vibration in overhead transmission lines. the vibrations are from wind passing over the lines and can lead to fatigue and failure overtime. The damper also absorbs and dissipate some of the energy and reduce impact on the line.

- Enhance system reliability – the spiral vibration dampers contribute to the reliability of installations. They also help prolong the lifespan of overhead transmission line by reducing wear and tear on the conductors.

- Prevent galloping – the dampers help prevent galloping which occurs when wind-induced vibrations. Galloping can put stress on the line and its support structures which leads to damage. this also helps to maintain the stability of the line.

- Improve safety – vibrations can lead to safety risk to personnel working near the lines and to the general public. The dampers help mitigate the risks by stabilizing the lines and reducing the likelihood of failures.

- Extended lifespan – the dampers help reduce the wear and tear on transmission line components. This helps extend the lifespan of the equipment and reduce the frequency of maintenance and repairs.

Designs for spiral vibration damper

The design of the spiral vibration damper helps to reduce vibrations in overhead transmission lines. The designs also provide durability, flexibility and adjustability to suit various operating conditions. The following are the various design elements of spiral vibration dampers.

- Spiral shape – the damper has a spiral-shaped structure configuration which allows absorption of vibrations.

- Attachment points – the damper attaches to the transmission lines conductor at many points along its length. They also help ensure the damper remains in place and dampens vibrations through the line.

- Ruggedness – the dampers have designs to withstand the rigors of outdoor use and exposure to harsh environmental conditions. This helps to provide durability to ensure long-term performance in demanding environments.

- Material – the dampers are from a durable and resilient materials such as aluminum, steel or composite materials. They provide ability to withstand environmental conditions and provide the damping characteristics.

- Flexible construction – construction of dampers provides flexibility allowing it to absorb and dissipate energy from wind-induced vibrations. This is without transferring excessive stress to the transmission line conductor.

- Adjustability – the dampers may have adjustable features to hold different transmission line configurations. This allows for optimal tuning of its damping characteristics to match the specific requirements.

Application areas of Stockbridge dampers

Spiral vibration dampers find use in infrastructure projects beyond power lines. Additionally, it is advisable to control and dampen vibrations induced by winds. They also enhance the reliability, safety and longevity of various structures and systems. Discussed below are the various applications of the spiral vibration dampers.

- Fiber optic cables – the dampers work in fiber optic cable installations which prevent damage to the cables. They also help to ensure reliable communication in various applications.

- Guyed masts and towers – these work in broadcasting applications which experience vibrations caused by wind loads.

- High-voltage power lines – the clamps work in high-voltage power lines that need maintenance. The dampers help prevent galloping and other dynamic instabilities that occur in high-voltage lines.

- Transmission and distribution lines – the dampers help to control wind-induced vibrations. They enhance the reliability and ensure uninterrupted electricity transmission.

- Suspension bridges – these dampers face wind-induced vibrations that impact their structural integrity and stability. The dampers can work on the bridge cables to mitigate these vibrations and reduce the potential for resonance.

- Railway electrification – the catenary wires are susceptible to vibration caused by train movements. Spiral vibration dampers can install along these catenary wires to reduce vibrations, reduce wear and tear. This is to mainly ensure reliable power supply.

- Industrial structures – the dampers work in industrial structures like cooling towers, chimneys or tall buildings. This ensures the stability and integrity of the buildings or industrial installations.

- Cable stayed bridges – these bridges use cables and towers to support the bridge deck to mitigate these vibrations. They also enhance the safety and functionality of the bridge.

- Wind turbine towers – wind turbines are subject to dynamic loads induced by winds which lead to tower vibrations. The dampers reduce the vibrations and enhance the structural integrity and performance of the turbines.

How to measure the tensile strength of the spiral vibration damper

The tensile strength of the spiral vibration dampers varies depending on various factors. These include material used, design and specific application requirements. They also have designs to withstand high tensile loads to ensure their effectiveness. Measuring the tensile strength involves putting the damper to a controlled tensile force until it breaks. Additionally, it is advisable to consult with experts for guidance on the tensile strength. The following is an overview of how to measure tensile strength of a spiral vibration damper.

- Prepare the damper – ensure the damper is in suitable condition for testing. It involves removing any external contaminants and ensure the damper is well attached to a testing apparatus.

- Mounting – mount the damper to a testing machine to allow for a straight and even application of force along its length.

- Initial measurement – measure and record the initial length and diameter of the damper. The measurements help to calculate the engineering stress and strain during the test.

- Apply tensile force – apply a tensile force to the damper using the testing machine at a constant rate until the damper breaks. Measure and record the applied force and the elongation or deformation of the damper.

- Calculate tensile strength – calculate the tensile strength of the damper using the recorded data. Tensile strength expresses in units of force per unit area.

- Documentation – record the testing procedure including the equipment used, applied force and tensile strength.

Challenges and issues facing use of spiral vibration damper

Spiral vibration dampers offer several benefits in reducing wind-induced vibrations. They also enhance the stability of the structures. Additionally, it is advisable to address these challenges to improve the design, materials and installation methods. The following are the several challenges and issues facing the use of spiral vibration dampers.

- Installation and maintenance costs – the installation process of the dampers must use specialized equipment and expertise. Periodic inspection and maintenance help to ensure the continued effectiveness of the ampers.

- Environmental conditions – the dampers face various environmental conditions. They include extreme temperature, humidity and exposure to UV radiation. These conditions degrade the materials and performance of the dampers to reduce the effectiveness of the lifespan.

- Effectiveness and performance – the dampers reduce vibrations and enhance the stability of the application. This depends on factors like design of the damper, frequency and size of wind-induced vibrations. The dampers help the applications to achieve optimal performance across diverse operating conditions.

- Compatibility and integration – the dampers should be compatible with the specific design and configuration of the structures. Ensure proper integration and alignment with existing infrastructure to enhance their performance.

- Dynamic loads and forces – transmission lines face dynamic loads and forces from various factors. These include ice accumulation, bird perching and mechanical impacts. Mitigating these dynamic loads can be challenging especially in regions with harsh weather conditions.

Frequently asked questions

A spiral vibration damper is a device used in electrical installation to reduce wind-induced vibrations and enhance stability.

Spiral vibration dampers work by absorbing and dissipating the energy generated by wind-induced vibrations. They reduce the amplitude of the vibrations and reduce stress on the conductors and support structures.

The design of the spiral vibration damper consists of a spiral-shaped structure made from durable materials. These include aluminum, steel or composites. Its design aims to be flexible, rugged and adjustable to dampen vibrations in various applications.

Spiral vibration dampers help reduce wind-induced vibrations, prevent galloping, enhance stability and extend the lifespan of transmission lines. they also improve safety and ensure reliable power transmission.

Spiral vibration dampers face various challenges such as installation and maintenance costs, compatibility and integration issues, environmental conditions and ensuring optimal effectiveness and performance.